The trailer concrete pump, a versatile and mobile concrete pumping solution, consists of a powerful pump unit mounted on a trailer. It is used to efficiently transfer and distribute concrete from a mixer truck or a concrete batching plant to the desired location on construction sites.

The equipment provides precise and controlled concrete placement, helping construction teams efficiently deliver the material to hard-to-reach areas that traditional methods struggle to access. It is a go-to pumping solution for varied construction needs. However, which kind of projects can you used the trailer concrete pump for? Continue to explore its applications in the next parapgrph.

Cases Show: Where Trailer Concrete Pumps Deliver Results

From remote infrastructure projects to tight urban job sites, contractors and builders worldwide rely on trailer concrete pumps to keep their most challenging builds on track. See how this versatile equipment solves concrete placement dilemmas across diverse construction applications.

Whether it’s a new house, home, villa, an office building, a hotel, or shopping mall, the trailer concrete pump for sale is a valuable asset in ensuring the smooth and efficient pouring of concrete foundations, floors, and other structural elements.

ABT30C – Operating in the Philippines

- Model: ABT30C diesel concrete trailer pump

- Project: Seaside resort construction

- Location: Siargao, Philippines

- Customer reviews: “Our team used the AIMIX concrete pump for the first time, receiving remote video guidance for debugging and operation training. We got started quickly, and the after-sales service exceeded our expectations.”

ABT40C – On-site Work in Indonesia

- Model: ABT40C diesel engine trailer concrete pump

- Project: Used for Villa Residential Construction

- Customer reviews: “A minor hydraulic fault occurred with the machine, but the after-sales team resolved it within 1 hours through online support, ensuring no delays in construction or pouring.”

Trailer concrete pumps are essential for pouring concrete at elevated levels, facilitating efficient and controlled delivery of concrete to the upper floors of high buildings and other tall structures.

ABT30C – Working in Indonesia

- Model: ABT30C diesel trailer concrete pump

- Project: Three-story Building

- Location: Kalimantan, Indonesia

- Customer reviews: “Easy installation and operation. Thanks to the local engineers’ guidance and support during equipment commissioning, we can put it into production soon!”

ABT40C – Operation in Philippines

- Model: ABT40C

- Project: Four-story Building

- Location: Manila, Philippines

- Customer reviews: “The small concrete pump delivered flawless performance on our four-story building project—powerful, reliable, and easy to maneuver. It kept our schedule tight and the concrete placement precise!”

From bridges and highways to dams and tunnels, it plays a vital role in the construction of large-scale infrastructure projects, ensuring the timely and accurate placement of concrete.

ABT80D – Working on-site in Peru

- Model: ABT80D electric type

- Project: 3km tunnel construction projects

- Location: Peru

- Customer reviews: “Electric startup in minutes, remote-controlled valve adjustment, and local tech support in Peru made the ABT80D effortless. We all like its smooth pumping operation too!”

The trailer concrete pumps for sale are essential in the construction of manufacturing facilities, warehouses, and other industrial buildings, where their ability to precisely deliver concrete to specific areas is crucial.

ABT40C – Used in the Philippines

- Model: ABT40C diesel type

- Project: Factory Construction

- Customer reviews: “Its fuel consumption was 15% lower than that of its competitors, and its maintenance was simple enough for workers to handle themselves. Ultimately, the factory construction was completed ahead of schedule.”

ABT40C – Work in Myanmar

- Model: ABT40C diesel type

- Project: Warehouse Construction in

- Customer reviews: “The diesel pump performed amazingly during the foundation pouring on-site – operating at high intensity for eight hours without any malfunctions.”

The versatility of trailer concrete pumps allows them to meet the diverse needs of various construction projects. Different projects require specific specifications and performance levels, leading to a range of trailer concrete pump models.

AIMIX, a leading manufacturer, offers several models designed to cater to different customer requirements. Each model has unique features that enable it to adapt to various construction conditions and needs. Below, we will introduce several common trailer concrete pump models in detail.

Different Models of Trailer Mounted Concrete Pumps

Common trailer concrete pump models for sale in AIMIX Group include the ABT40, ABT60, and ABT80. They all have diesel and electric types for choices. These models have different performance parameters to meet the needs of construction projects of varying scales.

40 m³/h Trailer Concrete Pump

- Model: ABT40C, ABT40D

- Capacity: 40 m³/h

- Max. vertical pumping distance: 120m

- Max. horizontal pumping distance: 500m

- Application: ideal for small to medium-sized construction projects, including residential buildings, commercial structures, and various infrastructure works. Its compact design makes it suitable for tight spaces and low-volume pours.

60 m³/h Tow Behind Concrete Pump

- Model: ABT60C, ABT60D

- Capacity: 60 m³/h

- Max. vertical pumping distance: 180m

- Max. horizontal pumping distance: 1000m

- Application: perfect for medium to large-scale construction projects, such as high-rise buildings, industrial facilities, and roadworks.

80 m³/h Trailer Pump

- Model: ABT80C, ABT80D

- Capacity: 80 m³/h

- Max. vertical pumping distance: 260m

- Max. horizontal pumping distance: 1200m

- Application: used for large-scale construction projects, including commercial buildings, infrastructure developments, and heavy civil engineering works.

Specifications

| Items | Units | ABT40C | ABT60C | ABT80C | |

|---|---|---|---|---|---|

| Whole performance of machine | Max. theo. concrete output(L./H) | M3/h | 40/26 | 67/45 | 84/45 |

| Max.concrete pumping pressure(H./L.) | MPa | 10/8 | 13/7 | 16/7 | |

| Distribution valve type | S Valve | S Valve | S Valve | ||

| Concrete cylinder diameter×stroke | mm | Φ180×1200 | Φ200×1650 | Φ200×1800 | |

| Hopper capacity x feeding height | L/mm | 400/1100 | 800/1400 | 800/1400 | |

| Outlet diameter | mm | Φ150 | Φ180 | Φ180 | |

| Power system | Diesel engine model | Weichai | Wechai | Wechai | |

| Diesel engineering power | KW | 82 | 129 | 176 | |

| Rotate speed | r/min | 2200 | 2200 | 2200 | |

| Hydraulic system | Circuit type | Open circuit | Open circuit | Open circuit | |

| Pumping system pressure | MPa | 32 | 32 | 32 | |

| Mixing system pressure | MPa | 10 | 10 | 10 | |

| Capacity of oil tank | L | 370 | 560 | 560 | |

| Other parameters | Max. Theoretical Vertical/Horizontal Conveying Distance | m | 120/500 | 180/1000 | 260/1200 |

| Max. aggregate diameter | mm | Slick/scree:40 | Slick/scree:40 | Slick/scree:40 | |

| Inside diameter of delivering pipe | mm | Φ125 | Φ125 | Φ125 | |

| Dimensions:length×width×height | mm | 5000x1850x1700 | 5800x2000x1750 | 6300x2100x2350 | |

| Total weight | kg | 4500 | 6500 | 6900 | |

| Items | Units | ABT40D | ABT60D | ABT80D | |

|---|---|---|---|---|---|

| Whole performance of machine | Max. theo. concrete output(L./H) | M3/h | 40/26 | 60/36 | 84/46 |

| Max.concrete pumping pressure(H./L.) | MPa | 10/8 | 13/7 | 16/9 | |

| Distribution valve type | S Valve | S Valve | S Valve | ||

| Concrete cylinder diameter×stroke | mm | Φ180×1300 | Φ200×1650 | Φ200×1800 | |

| Hopper capacity x feeding height | L/mm | 400/1250 | 800/1400 | 800/1400 | |

| Outlet diameter | mm | Φ150 | Φ180 | Φ180 | |

| Electrical engineering power | KW | 45 | 90 | 110 | |

| Rotate speed | r/min | 1480 | 1480 | 1480 | |

| Hydraulic system | Circuit type | Open circuit | Open circuit | Open circuit | |

| Pumping system pressure | MPa | 28 | 28 | 32 | |

| Mixing system pressure | MPa | 10 | 10 | 10 | |

| Capacity of oil tank | L | 370 | 560 | 560 | |

| Other parameters | Max. Theoretical Vertical/Horizontal Conveying Distance | m | 120/500 | 160/800 | 200/1000 |

| Max. aggregate diameter | mm | Slick/scree:40 | Slick/scree:40 | Slick/scree:40 | |

| Inside diameter of delivering pipe | mm | Φ125 | Φ125 | Φ125 | |

| Dimensions:length×width×height | mm | 4500x1750x1600 | 5500x2000x1750 | 5800x2100x2350 | |

| Total weight | kg | 3200 | 6000 | 6300 | |

Tailored Solutions: Elevate Your Projects with Integrated Equipment

In many construction projects, a single trailer concrete pump often falls short. A lot of construction projects require more flexible and comprehensive solutions to meet various working conditions and needs. By pairing with specialized equipment, like self loading concrete mixer and transit mixer truck, you can optimize the efficiency, productivity, and cost-effectiveness of the concrete operations.

Innovative Solution 1: Concrete Trailer Pump + Self Loading Concrete Mixer

- Function: The self loading concrete mixer has multi-functions, especially self-loading features, making it distinguished from an ordinary concrete mixer truck. After concrete mixture is finished mixing, it will be discharged into the trailer pump.

- Advantages: This setup enhances construction efficiency by reducing labor requirements and simplifying vehicle coordination.

- Applications: Ideal for rapid and flexible concrete placement, particularly in road construction and foundation work. Common Combo: ABT40+AS-3.5; ABT60+AS4.5; ABT60+AS-5.5

Common Solution 2: Trailer Concrete Pump + Concrete Mixer Truck

- Function: The concrete mixer truck is responsible for transporting the concrete from the batching plant or factory to the construction site, while the concrete pump trailer is responsible for mixing and transporting the concrete to the point of placement.

- Advantages: improve concrete transportation efficiency and reduce labor and equipment requirements.

- Applications: suitable for large or dispersed concrete pouring projects, such as high-rise buildings, large-scale bridges, etc.

It is worth noting that if you want to seek concrete mixing and pumping solutions for small or medium-sized projects, Innovative Solution 1 will be your best choice. Because the price of Solution 1 is much lower than Solution 2 and is more likely to be within your budget. In addition, the Innovative Solution 1 is popular among the construction market.

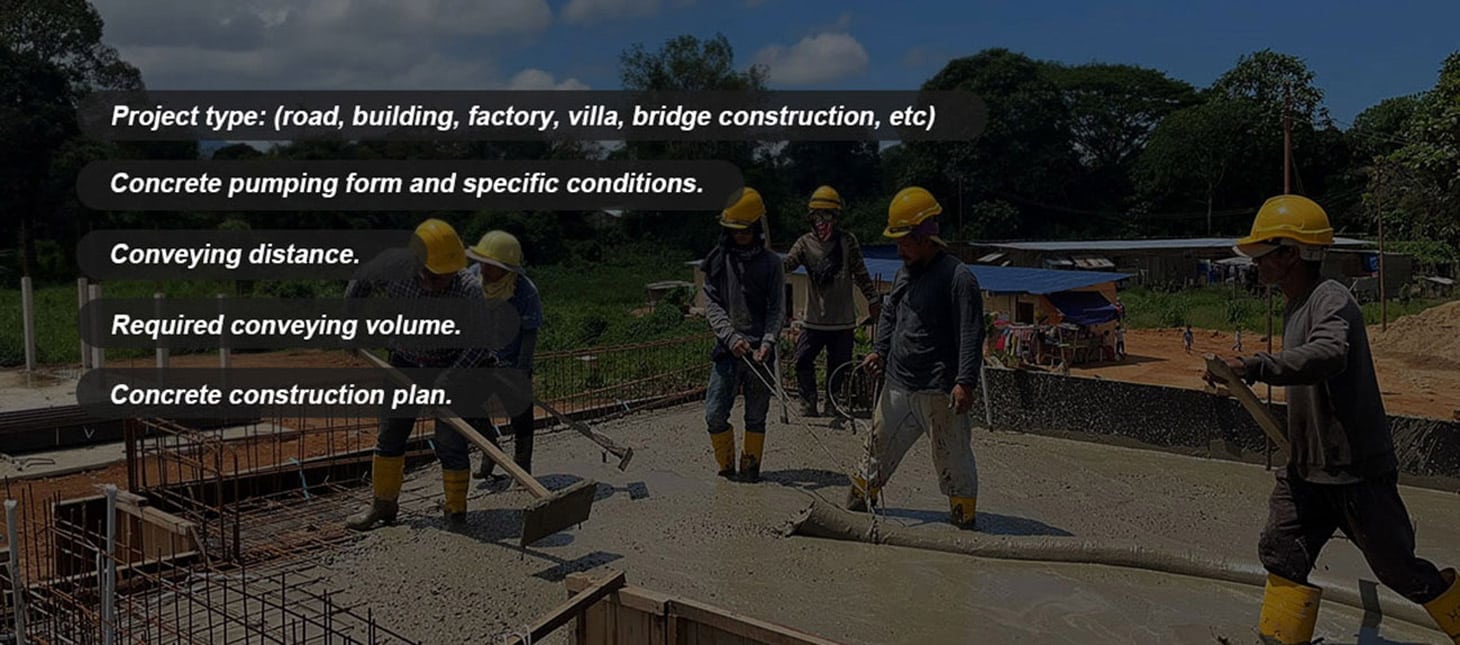

How to Choose a Suitable Trailer Mounted Pump Model: Key Considerations

When selecting a trailer concrete pump for sale in the market, it’s essential to consider several key factors that go beyond just the specifics of your projects, such as output capacity and power system. Here are some crucial points to consider:

Project Size and Requirements

The size and specific requirements of your construction project should be a key consideration. Smaller projects may only need a compact, lower-output pump, like ABT30, ABT40; while large-scale infrastructure jobs will require a high-capacity model, like ABT80, ABT90. Evaluating factors like project scale, concrete volume needed, and accessibility of the site can help determine the appropriate pump size.

Output Capacity

The output capacity of trailer concrete pumps typically ranges from 40 to 80 cubic meters per hour. This wide range can accommodate the needs of a variety of construction projects, from smaller residential builds to large-scale infrastructure. If output capacity is your primary concern, you can rest assured that there are options available to meet your specific requirements.

Power System

Another important factor is the power system of the trailer concrete pump. The two main options are diesel-powered and electric-powered models. Each has its own advantages – diesel concrete pumps offer greater mobility and flexibility, while electric pumps are quieter and more environmentally friendly. Evaluating your project’s power needs and access to power sources can help determine the best power system for your requirements

Guidance on Model Selection Based on Building Construction Project

Taking the building construction projects for example, selecting the right equipment is essential for efficiency and quality in building construction projects. The chosen model significantly affects the speed and effectiveness of concrete placement, particularly as building heights increase.

The table below outlines recommended trailer pump models based on the number of floors in a building. Each model is suited to specific construction heights, ensuring optimal performance and reliability.

| Building Floors | Recommended Model |

|---|---|

| 2-3 floors | ABT30 |

| 3-10 floors | ABT40 |

| 10-15 floors | ABT50 |

| 15-28 floors | ABT60 |

| 35 floors | ABT80 |

| 35-50 floors | ABT90 |

If you’re unsure how to choose a suitable one, don’t worry. The best way is to reach out to us for guidance. You can contact AIMIX through the inquiry form. We will work with you to understand your project details and recommend the most suitable trailer concrete pump model. And you can choose one from AIMIX Group with safety. Here are some reasons why you can cooperate with us.

Why Buy Trailer Concrete Pump from AIMIX?

In the market, there are a lot of trailer concrete pump manufacturers. Why choose to buy concrete pump trailer near me in AIMIX? Here are some important reasons you may be convinced of.

Certificate Ensured

AIMIX Group has manufactured cement pump trailer for sale for decades since 1982. With over 30 years of manufacturing experience, AIMIX is bound to provide customers with high-quality trailer line pump. AIMIX has gained CE certificate to ensure quality of concrete pump machine.

Application Worldwide

Since manufacturing, AIMIX has exported countless sets of concrete trailer pumps for sale to help solve civil engineering problems all over the world. Our concrete pumps have covered over 100 countries, including Philippines, Indonesia, Malaysia, Chile, Kenya, Canada, Germany, USA, UK, UAE, Nigeria, Somalia, Malawi, Australia, Russia, Uzbekistan, Sri Lanka, Bangladesh, Peru, Korea, Vietnam, Thailand, Laos, Myanmar, etc… You can explore various concrete pump case studies by selecting your country on the map below.

Considerate After-sales Service Provided

Up to now, Aimix has established several overseas offices, like in the Philippines, Indonesia, Malaysia, Russia, Uzbekistan, UAE, etc. In this way can we offer prompt concrete trailer pump service near me for global customers. In the future, we would build more offices in many countries! Therefore, customers don’t worry about this issue for concrete trailer pump for sale.

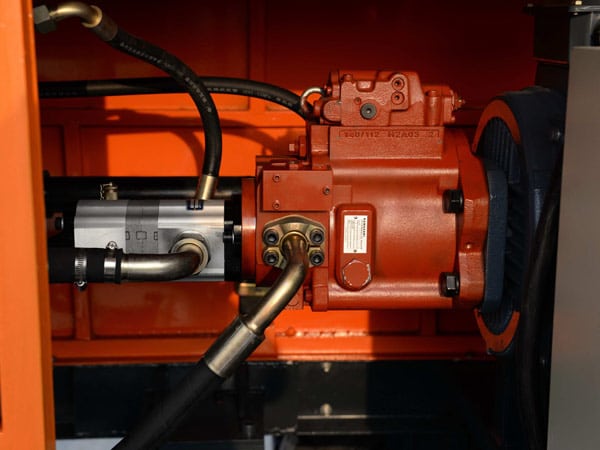

Components from Famous Brand

Aimix has adopted some components from famous brands. It not only can improve working efficiency, but is easier for customers to find the components if they are broken out. For example, for the diesel engine, we use the domestic Wechai and foreign Cummins brands; the main oil pump adopts the well-known brand Kawasaki; the hydraulic hoses come from American Eaton; the electric control system adopts Omron…… Using these components with the famous brand not only can greatly improve the performance of machine, but prolongs the service life.

With these advantages, many global clients have chosen AIMIX towable concrete pumps for sale. Apart from that, AIMIX tow-behind concrete pumps stand out due to their advanced systems. These systems are designed for optimal performance, reliability, and ease of use, ensuring that contractors and construction companies can efficiently manage their concrete placement needs. Continue to explore its systems.

Advanced Systems of Trailer Concrete Pumps: Ensuring Stable Performance

Robust Power System

- Weichai Engine: This powerful and reliable engine ensures high-intensity continuous operation, reducing the likelihood of downtime and operational costs. Its global service network facilitates efficient maintenance, ensuring that the pumps remain in peak condition.

- Kawasaki Main Oil Pump: Featuring a dual-pump dual-circuit hydraulic system, this pump simplifies fault diagnosis and enhances longevity, providing superior performance throughout the pump’s lifecycle.

Superior Hydraulic System

- Extended Lifespan: The hydraulic system is designed to increase operational life by 10%, while also reducing maintenance time by 50% and lowering parts replacement costs.

- Parker Sealing Technology: This innovative technology minimizes leaks in hydraulic cylinders, improving wear resistance and corrosion protection for enhanced durability.

Sturdy Chassis Design

- High-Strength Steel Frame: The robust chassis design enhances safety and impact resistance, ensuring the equipment can withstand tough site conditions.

- Versatile Towing System: With a multi-mode towing system, the pumps can be easily adapted for use with trailers, forklifts, and loaders, improving efficiency during transitions between job sites.

Intelligent Control System

- High Continuity Rate: The intelligent control system guarantees a construction continuity rate of 98%, significantly boosting productivity and minimizing delays.

- Dual Control Options: Featuring both cab and remote control capabilities, this system allows for precise operation and reduces the risk of human error during concrete placement.

Superior Benefits of Opting for a Towable Concrete Pump Over Other Types

Concrete pumps come in various configurations, each with its own advantages. Among the different types, the trailer-mounted concrete pump may be your best concrete pumping solution due to its economical. Here are some of the key advantages it offers over other type of concrete pump options:

- Cost-Effectiveness: Compared to boom concrete pumps, trailer-mounted pumps are generally more cost-effective. The concrete trailer pump price is much cheaper than boom pump price.

- Versatility in Application: Compared with mixer pump, the trailer-mounted concrete pum has wider range capacity. It can be applicable for various scales of construction projects, including small, medium, and large. While the concrete mixer pump with small capacity is only suitable for small rural and urban construction projects.

- Accessibility in Challenging Locations: In contrast to concrete boom pumps, which are primarily designed for large construction sites with ample open space, trailer mounted pumps excel at placing concrete in confined or hard-to-access areas. This makes them an ideal concrete pumping solution for projects involving tunnels, water conservation efforts, and other specialized construction scenarios.

Therefore, the trailer pump would be the most suitable one for your project. What would you consider if you plan to invest in one? There is no doubt of its price. Continue to find best prices in AIMIX.

How Much is A Concrete Pump Trailer?

To start the concrete pump trailer business, it is necessary to know the concrete pump trailer cost clearly first. Before making an order, you can compare the prices in different trailer concrete pump companies. When comparing the price for trailer concrete pump, it is better to consider these factors, such as types of trailer concrete pump with boom, trailer concrete pump capacity, pumping distance, after-sales service, etc. Here I have listed AIMIX concrete trailer pump price for reference:

- ABT40C / ABT60C / ABT80C / ABT90C Price Ranges: $24,000-$60,000

If you want to get the latest quotation for concrete trailer line pump for sale, welcome to contact us right now.

How Does A Concrete Trailer Pump Work?

A trailer concrete pump is a mobile and versatile machine used for transferring liquid concrete (or mortar) from a mixer to the desired location at a construction site. It consists of several systems that work together to facilitate the pumping process. Here is the detailed explanation of the trailer concrete pump working process.

Before starting the pumping process, the trailer concrete pump needs to be positioned at the desired location on the construction site. The stabilizing outriggers are extended to provide stability to the machine during operation.

The hopper is loaded with concrete from the mixer. The concrete is either poured directly into the hopper or transferred using a conveyor belt or crane.

Inside the hopper, a mixing device continuously rotates to prevent the concrete from settling and to maintain its consistency. It ensures that the concrete remains fluid and ready for pumping.

Pumping: With the hopper loaded and the concrete properly mixed, the pumping process begins. The trailer pump operator starts the engine or motor, activating the hydraulic system. The concrete is pushed into the pumping cylinders by the reciprocating action of the hydraulic pistons or cylinders.

The concrete flows from the pumping cylinders into the pipes, which are connected to a flexible delivery line. The pipes and delivery line are designed to withstand the high pressure of the concrete. The delivery line is usually equipped with a nozzle or a boom that can be maneuvered to place the concrete accurately at the desired location.

After the concrete pumping process is complete, any remaining concrete in the system needs to be flushed out. Cleaning can be done by pumping water or a cleaning agent through the pipes and delivery line to remove any residual concrete and prevent blockages.

Here is an working video for reference. You can visually understand the entire working process of it.

The concrete pump tow behind may encounter faults during operation, and pipe blockages are a common problem. Pipe blockages not only affect the pumping efficiency, but also may lead to equipment damage and increased maintenance costs. Therefore, taking effective preventive measures is particularly important. Next, we will explore some feasible methods to help you better protect your concrete pump trailer and ensure that pipe blockages are avoided during routine operations.

How To Prevent Trailer Pump from Pipe Blockages During Work?

Ensure Proper Installation

When installing concrete pipes, workers should try to avoid excessive bending to reduce the resistance of concrete transportation.

Maintain Operational Continuity

The continuity of specific operations should be maintained. The operation interval should not be too long to prevent the concrete from solidifying. If the interval is too long for some reason, the pump should be turned on every 10 minutes, or in any case, the pump should be rotated several times.

Adhere to Concrete Mix Ratios

The concrete ratio requirements are strictly in accordance with the specified ratio.

Follow Aggregate Specifications

Every pump has requirements for aggregates. Please read the instructions before the concrete pump operation. The aggregation should not be greater than the specified aggregation.

Lubricate and Clean Pipes Properly

Before the operation, the pipes should be lubricated with water, first with a thinner mortar, and then with concrete. Besides, after working, the pipes should be cleaned timely.

Utilize Anti-Pumping Feature

Most importantly, AIMIX concrete pump has unique features – an anti-pumping function. In this way, the concrete trailer pumps for sale near me also can return to normal working conditions after the concrete pipes block.

If you have any question when operating the trailer concrete line pump for sale, contact us timely for solutions.

Names Referring to Concrete Trailer Pump

In the international market, customers call it by different names. First, let’s check its names. The trailer concrete pump is often referred to by various names like “tow behind concrete pump,” “stationary concrete pump,” and “concrete line pump,” each highlighting a specific characteristic or use of the equipment:

- Tow Behind Concrete Pump: It emphasizes the mobility of the pump. The pump is designed to be towed behind a vehicle, allowing it to be easily transported from one site to another. This feature is particularly useful for projects that require frequent relocation of the equipment.

- Stationary Concrete Pump: This term focuses on the stationary concrete pump’s ability to remain in a fixed position during operation. While the trailer concrete pump is portable, once it is set up at a construction site, it typically stays in place to pump concrete over long distances.

- Concrete Line Pump: This name refers to the pump’s method of delivering concrete through a series of pipes or hoses, known as the “line.”

Therefore, no matter what the trailer concrete pump is called, it will be your best helper for various kinds of construction projects. Tell us your specific requirements through the following form or whatsapp us. Later AIMIX sales manager will contact you.