One Machine, Two Functions – Twice the Efficiency

Ready StockFast Delivery

Export countries 150+Global 100+ Service Outlets

Are you struggling with the inefficiency of separate mixing and pouring processes? The innovative concrete mixer with pump would be your ultimate all-in-one solution that slashes time and manpower while boosting output. This integrated concrete mixing pump not only blends concrete mixture, but delivers it directly to the placement point, eliminating costly delays and manual handling. It has been the primary choice for contractors and builders applying to their construction projects.

Three Concrete Mixer with Pump Types, One Solution for Your Job Site

To meet diverse construction challenges, AIMIX has launched three types of concrete mixer pumps for sale. One is with a drum concrete mixer, one is with the planetary mixer, and the last one is with a boom. They’re dedicated concrete mixing and pumping solutions for different operating scenarios. Check their differences, and there’s always a model that matches your construction project needs.

If your project requires concrete strength of C30 or below and you’re looking for the ultimate value for money, this classic drum type mixer pump for sale is your ideal partner. Utilizing the proven principle of drum rotation and gravity-fed concrete, it’s designed specifically for mixing low to medium-strength concrete. Its simple structure reduces purchase costs and maintenance requirements, providing a reliable concrete solution for a wide range of applications, including residential and rural construction.

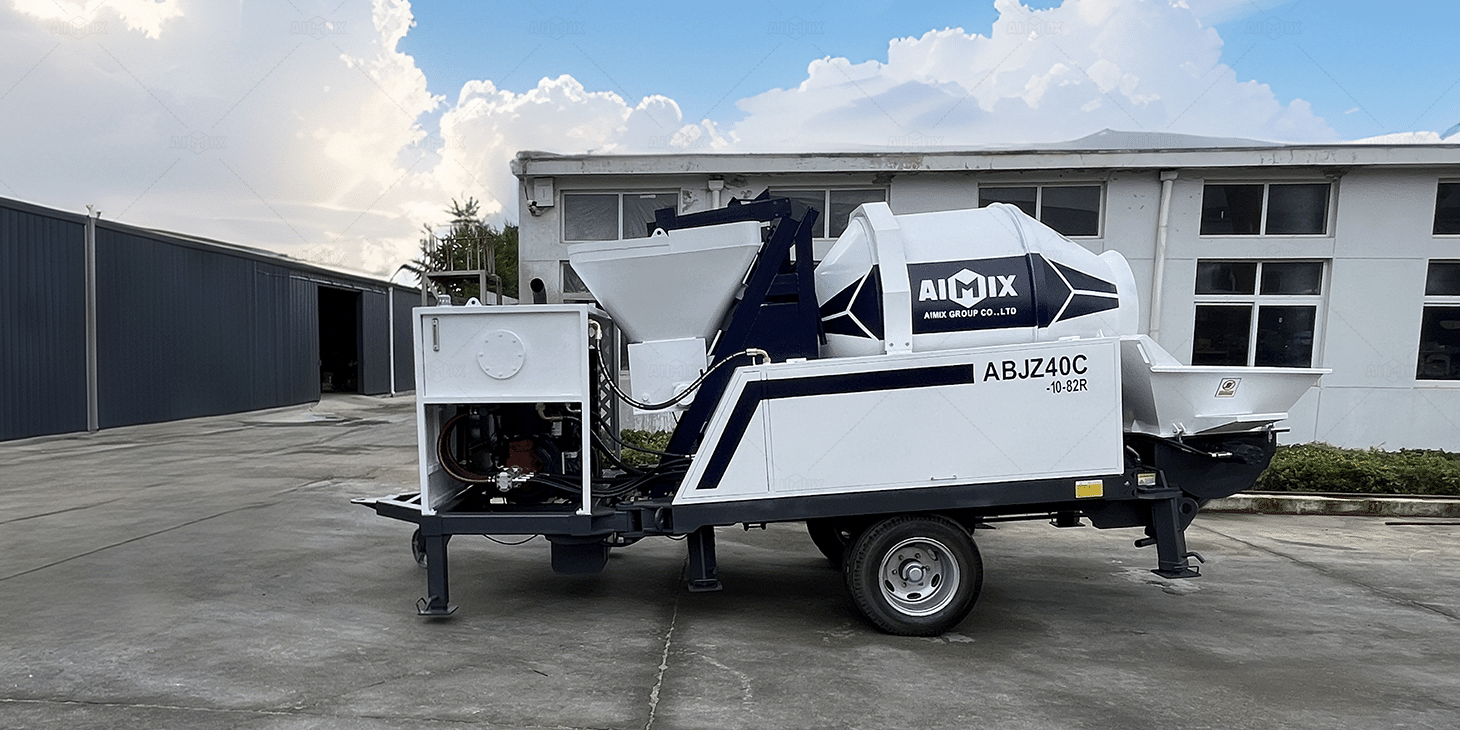

Classic ABJZ Series – Concrete Pump with Drum Mixer – Flexible and Economical Option

Models: ABJZ30C, ABJZ40C diesel type; ABJZ30D, ABJZ40D electric type

Applications: Suitable for small to medium-sized urban construction, residential buildings, road maintenance, etc

30 and 40m³/hConcrete Output

Diesel or ElectricPower Type

Horizontal Pumping300-500m

Vertical Pumping120m

Are you still worried about inflated production figures on your equipment? Or quality fluctuations due to artificial batching? It’s time to say goodbye to these hidden dangers. AIMIX has designed the vertical planetary mixer concrete pump, designed not for specifications, but for your actual output. See how achieving production targets and maintaining consistent quality become the norm on your construction site.

New ABJW40C – Concrete Pump with Vertical Shaft Planetary Mixer – Efficient Mixing Capability

Equipped Planetary Mixer: Dual hydraulic drive, mixing without dead angle, more uniform mixing

Capability: 2.5 m³ mixing tank; Achieve 40-60 m³/h capacity

40-60 m³/hConcrete Output

9MPaConcrete Pumping Pressure

WeichaiDiesel Engine Model

S ValveDistribution Valve

The two ABJZ series and ABJZ series introduced earlier are the small capacity concrete mixer pumps for sale in AIMIX Group. While they perform well in many small or medium-sized construction projects, they can be challenging to deliver concrete at heights and over long distances. Especially when projects involve high-rise buildings or relative larger infrastructure, the delivery capacity is often limited.

To tackle these challenges, AIMIX introduces the APY Series Boom Concrete Mixer Pump. It is a powerful 3-in-1 solution that integrates mixing, pumping, and placing into a single, highly efficient machine. Equipped with a high-performance planetary mixer for perfect concrete mix homogeneity and an agile placing boom for superior reach and precision, the APY series boom pump mixer delivers an all-in-one operational workflow. It eliminates the need for multiple equipment pieces and dramatically boost on-site productivity.

Crawler Boom Concrete Pump with Planetary Mixer – 15m and 18m

Crawler Chassis: Designed to navigate various terrains with ease, ensuring stable and efficient operation.

Smart Control System: Choose between intuitive panel control or convenient remote control for precise operation.

50(m3/h)Max. Pumping Capacity

2-4 km/hCrawling Speed

±180Rotation Angle

3Boom sections

Wheeled Boom Pump with Planetary Mixer – 20m and 26m

Effortless Mobility: Equipped with durable tires for smooth and easy movement on flat roads without licence limited.

Enhanced Efficiency: Planetary mixer boosts mixing performance, increasing productivity by 20%.

600mHorizontal Pump Distance

80mVertical Pump Distance

5Boom Sections

Panel or WirelessControl

Applications of Concrete Mixer Pumps in Construction Industries

The construction industry is a broad and diverse field that involves the construction of everything from residential and commercial buildings to industrial facilities and infrastructure projects. The concrete mixer pump trailer is appliable various fields, such as residential construction, commercial construction, industrial construction and concrete road construction. Here are some cases of AIMIX concrete pump applications for reference.

ABJZ40C – Diesel Mixer Pump for Factory Construction

- Model: ABJZ40C; 40 m³/h

- Pumping Distance: 120m vertically; 500m horizontally

- Power type: Weichai brand diesel engine

- Customer reviews: “It has greatly improve working efficiency. Now it can produce over 10 cubic meters concrete mixture per hour. Strongly recommending for this equipment!”

ABJZ40C – Diesel Concrete Pump Mixer for Warehouse Construction

- Model: ABJZ40C; 40 m³/h

- Project location: Philippines

- Pumping Distance: 120m vertically; 500m horizontally

- Customer reviews: “Now my warehouse construction project is almost finished thanks to the use of the AIMIX concrete pump and mixer. It has accelerated the progress of the project. ”

ABJZ40C – Diesel Concrete Mix Pump for Road Work

- Projects: concrete road construction

- Pumping Distance: 120m vertically; 500m horizontally

- Customer reviews: “ABJZ40 model can pump concrete for a long distance, up to 500 meters. During the construction of the entire 3km roads, we only moved it a few times, and it was very convenient to move.”

ABJZ40C – Diesel Mixer Concrete Pump for Mosque Construcion

- Capacity: 40 m³/h

- Pumping pressure: 10Mpa

- Pumping Distance: 120m vertically; 500m horizontally

- Customer reviews: “It completely replaced the original method of using concrete mixers to produce concrete and manually transporting concrete. The mixer pump concrete have helped me save costs, especially labour costs.”

ABJZ40D – Electric Concrete Pump Mixer for Seaside Work

- Project items: Seaside Trestle Project

- Pumping Distance: 120m vertically; 500m horizontally

- Customer reviews: “My project is very challenging because it is to be constructed at sea, which increases the difficulty of pumping. However, I am very satisfied with the pumping solution provided by AIMIX.”

On-site Working Video Collections

They Put Me on a Boat… Now I’m Pouring Concrete at Sea!

Your Next New House? Let me Help Create It!

Call Me A Underground Hero, Foundations Are My Specialty!

New Owner Take me Home, Get This Job Pumping!

Customized Concrete Solutions: Save Time & Money for Your Project

Construction projects need speed and smart planning. We know every project is different, some need fast material delivery, others need perfect concrete mix. That’s why we mix and match equipment, like concrete mixer pump with other machines, to fit your exact needs. These solutions can help you save time, cut costs, and build better.

Solution 1. Wheel Loader + Concrete Mixer Pump | Fast & Simple Setup

Best for:

Construction sites with open space and raw material transport, like foundation work, road bases, and rural house construction.

How Does it Work:

The wheel loader acts like a “material mover”, quickly loading sand, gravel, and cement into the mixer pump with its bucket and easy movement. The mixer pump then keeps working non-stop, mixing and pumping concrete smoothly.

What you gain:

- Faster progress: No waiting for materials. The mixer pump runs continuously, boosting daily output by over 30%.

- Fewer workers needed: Replaces 3–4 workers moving materials by hand; now just 1 loader operator does the job, saving about $2,000/month in labor.

Solution 2. Wheel Loader + Concrete Batching Machine + Concrete Mixer Pump | Perfect Mix for Quality Projects

Best for:

Projects needing precise concrete, like commercial buildings, small bridges, waterproof structures, etc.

How it works:

The wheel loader moves raw materials to the batching machine. The concrete batcher automatically weighs each ingredient to the exact recipe. The mixer pump then mixes it perfectly for high-quality concrete.

What you gain:

Specifications

When determining if a particular model is suitable for your projects, you should consider its main parameters. Review their specifications below.

| Items | Units | ABJZ30C | ABJZ40C |

|---|---|---|---|

| Max. theo. concrete output(L./H) | M3/h | 30 | 40 |

| Mixer rated feed capacity | m3 | 0.56 | 0.56 |

| Mixer rated discharge capacity | m3 | 0.35 | 0.45 |

| Max.concrete pumping pressure(H./L.) | MPa | 10 | 10 |

| Distribution valve type | S Valve | S Valve | |

| Concrete cylinder diameter×stroke | mm | Φ140×1000 | Φ180×1000 |

| Hopper capacity | L | 400 | 400 |

| Outlet diameter | mm | Φ150 | Φ150 |

| Diesel engine model | Weichai | Weichai | |

| Electrical engineering power | KW | 37 | 82 |

| Rotate speed | r/min | 1480 | 2200 |

| Circuit type | Open circuit | Open circuit | |

| Pumping system pressure | MPa | 26 | 32 |

| Mixing system pressure | MPa | 6-8 | 6 |

| Capacity of oil tank | L | 260 | 350 |

| Max. Theoretical Vertical/Horizontal Conveying Distance | m | 120/300 | 120/500 |

| Max. aggregate diameter | mm | Slick/scree:10/20 | Slick/scree:40/50 |

| Inside diameter of delivering pipe | mm | Φ100 | Φ125 |

| Dimensions:length×width×height | mm | 4500x1750x1600 | 600x2300x3150 |

| Total weight | kg | 3000 | 4500 |

| Items | Units | ABJZ30D | ABJZ40D | ABJS40D-JS500 | ABJS40D-JS750 |

|---|---|---|---|---|---|

| Max. theo. concrete output(L./H) | M3/h | 30 | 40 | 40 | 40 |

| Mixer rated feed capacity | m3 | 0.56 | 0.56 | 0.56 | 0.56 |

| Mixer rated discharge capacity | m3 | 0.35 | 0.45 | 0.5 | 0.75 |

| Max.concrete pumping pressure(H./L.) | MPa | 10 | 10 | 8 | 8 |

| Distribution valve type | S Valve | S Valve | S Valve | S Valve | |

| Concrete cylinder diameter×stroke | mm | Φ140×1000 | Φ180×1000 | Φ200×1000 | Φ200×1000 |

| Hopper capacity | L | 400 | 400 | 400 | 400 |

| Outlet diameter | mm | Φ150 | Φ150 | Φ180 | Φ180 |

| Winding motor power | KW | 5.5 | 5.5 | 5.5 | 7.5 |

| Stir the motorPower | KW | 4.5 | 4.5 | 18.5 | 30 |

| Water pump motor powe | KW | 0.55 | 0.55 | 0.75 | 0.75 |

| Electrical engineering power | KW | 37 | 45 | 45 | 45 |

| Rotate speed | r/min | 1480 | 1480 | 1480 | 1480 |

| Circuit type | Open circuit | Open circuit | Open circuit | Open circuit | |

| Pumping system pressure | MPa | 26 | 26 | 28 | 28 |

| Mixing system pressure | MPa | 6-8 | 6-8 | 6-8 | 6-8 |

| Capacity of oil tank | L | 260 | 370 | 370 | 370 |

| Max. Theoretical Vertical/Horizontal Conveying Distance | m | 120/300 | 120/500 | 120/500 | 120/500 |

| Max. aggregate diameter | mm | Slick/scree:10/20 | Slick/scree:40/50 | Slick/scree:40/50 | Slick/scree:40/50 |

| Inside diameter of delivering pipe | mm | Φ100 | Φ125 | Φ125 | Φ125 |

| Dimensions:length×width×height | mm | 4500x1750x1600 | 4200x2300x3150 | 4200x2300x3150 | 6000x2300x3150 |

| Total weight | kg | 3000 | 4500 | 4500 | 5000 |

| Item | Unit | ABY-15 | ABY-18 | |

|---|---|---|---|---|

| Parameter | Maximum theoretical delivery volume | M3/h | 50 | 50 |

| Maximum outlet pressure | MPa | 6 | 6 | |

| Distribution valve type | S valve | S valve | ||

| Inlet and outlet switching interruption time/switching frequency | 0.3-0.5/19 | 0.3-0.5/19 | ||

| Transmission cylinder material | High quality steel chrome plated | High quality steel chrome plated | ||

| Main cylinder specifications (cylinder diameter x stroke) | mm | Ø125x1000 | Ø125x1000 | |

| Cylinder diameter x stroke | mm | Ø230x1000 | Ø230x1000 | |

| Outlet diameter | mm | 180 | 180 | |

| Operational Controls | Panel and wireless remote control | Panel and wireless remote control | ||

| Powertrain | Rated power | KW | 110 | 110 |

| Rated speed | rpm | 1800 | 1800 | |

| Hydraulic system | Main oil pump model | K3V112 | K3V112 | |

| Manufacturer | Kawasaki | Kawasaki | ||

| Main oil pump displacement | Ml/r | 112 | 112 | |

| Main oil pump quantity | 1 | 1 | ||

| Main hydraulic system form and control | Open loop electric proportional control | Open loop electric proportional control | ||

| Main system rated pressure | Mpa | 32 | 32 | |

| Distribution system pressure | Mpa | 32 | 32 | |

| Hydraulic oil tank capacity | L | 450 | 450 | |

| Boom Frame Parameters | Length of one arm | mm | 5150 | 6000 |

| Length of two arms | mm | 4300 | 4760 | |

| Length of three arms | mm | 2550 | 4760 | |

| Turntable angle | ±180 | ±180 | ||

| Diesel Engine | Rated power | kW | 110 | 110 |

| Control voltage | V | 24 | 24 | |

| Maximum speed | r/min | 1800 | 1800 | |

| Concrete Mixer | Disc type | m3/h | 1.5 | 1.5 |

| Other parameters | Hydraulic oil cooling method | Air Cooling | Air Cooling | |

| Overall dimensions (length x width x height) | mm | 6000*2200*2900 | 6500*2200*3100 | |

| Tracks | T | 10 | 10 | |

| Travel speed | Km/H | 45326 | 45326 | |

| Overall weight | kg | 12500 | 13500 | |

Most Important Specifications of Concrete Mixer Pump You Should Pay Attention to:

- Output Capacity: how much concrete the pump can deliver per hour, like 30m³/h, 40m³/h, and 60m³/h. Higher capacity suits large-scale projects.

- Power Source: Diesel or electric. Diesel engine mixer pump suit for remote sites without stable electricity; electric type is suitable for where the site has reliable power supply , common for urban projects.

- Max Horizontal and Vertical Pumping Distance: Ensure the mini concrete mixer and pumping machine can reach all parts of your construction site, especially for high-rise buildings or extensive road projects.

- Max aggregate diameter: estimate aggregate particle size and ensure it is within range to avoid frequent concrete pipe blockage.

Choose A Suitable Concrete Mixer Pump Model According to Your Project Needs

Choosing the right concrete mixer pump machine model is crucial for the success of your construction projects. The appropriate model can significantly impact the efficiency, quality, and cost-effectiveness of your operations. Whether you’re working on which kind of project, selecting the suitable concrete mixing and pumping machine ensures that your specific needs are met. Here are some important aspects that you need to consider carefully.

Project Type & Concrete Demand

-

The nature and scale of your project dictate the required output and concrete mixer pump type.

- Small to Medium-scale Projects: Residential buildings, villas, rural construction, and irrigation channels typically require a lower output of 30-40 m³/h.

- Large-scale & Commercial Projects: Industrial plants, high-rise buildings, and bridgesdemand higher output, like 50 and 60 m³/h or more, and often more powerful pumping pressure.

- Specialized Projects: For projects with limited access, complex terrain, or wide sites, like ports or tunnels, mobility and reach become crucial.

Pumping Distance & Height

-

Determine the maximum distance the concrete needs to be pumped, both horizontally and vertically. This is a primary factor in selecting the concrete mixing pump’s engine power and pressure. Always provide a buffer beyond your calculated distance to account for pipeline bends and resistance.

Site Conditions & Power Availability

-

The infrastructure at your construction site is a decisive factor.

- Diesel type: Ideal for remote sites or new projects with no stable electricity supply. They offer excellent mobility and power but have higher noise levels.

- Electric type: Best for sites with a reliable and sufficient power supply (check voltage requirements, e.g., 380V/415V). The electric concrete pumps are quieter, more cost-effective to run, and produce zero emissions, making them suitable for indoor or urban projects.

Concrete Mix Design & Material Properties

-

The pump must be compatible with the concrete you are using. Inform the manufacturer about the mix design, including:

- Aggregate Size: Maximum size of stone or gravel.

- Slump Value: The workability of the concrete.

- Special Mixes: Such as lightweight concrete, fiber-reinforced concrete, or mortar, which may require specific pumping systems.

Mobility & Access

- Wheeled Models: Excellent for moving between different sites or on large, open areas with good road access.

- Tracked Models: Perfect for confined spaces, soft or uneven terrain, and projects requiring superior on-site maneuverability without a trailer.

After considering the above aspects carefully, you can primarily select a model of concrete mixer with pump machine is more appropriate for you. And there is a simple recommendation on the selection according to projects.

| Types of Projects | Recommended Models |

|---|---|

| Rural and urban and rural 2-3-story houses, small foundations, small infrastructure projects | ABJZ30, ABJZ40, ABJW40 |

| Small and medium-sized residential projects, commercial buildings, Small prefabricated component factory | ABJZ40, ABJW60 |

| Tunnel construction, water conservancy projects, terrace construction, mountain villas, swamp backfill, etc. | Crawler type ABY15 |

| Small and medium-sized industrial parks, municipal projects, and township community construction, 6-8 floors of buildings | Wheeled type ABY20 and ABY26 |

If you still have no idea, you just need provide key information about the projects as listed above for us. AIMIX sales manager will guide you to choose a right concrete pump with mixer machine. Feel free to contact us now!

Best Concrete Mixer with Pump Service Provided by Us

Aimix Group is dedicated to offering considerate mobile concrete mixer with pump for sale service for our customers all over the world. Indeed, we can provide all-around service for customers, including pre-sale service, on-sale service, and after-sales service. Here is the introduction of what service exactly can Aimix offer from three aspects!

Pre-Sale Consultation & Planning

- Our experts are online 24/7 to provide initial consultations. We will offer personalized equipment recommendations. By analyzing your project specifics, such as required output, pumping height and distance, and site conditions, we help you select the perfect model, whether it’s a compact trailer type for rural construction or a high-output boom pump mixer for industrial projects.

On-Sale Support & Customization

- During the sales process, your 1-to-1 professional sales manager would be always here! He facilitates factory-direct price negotiations and detailed order confirmation. The sales manager also coordinate customization options, such as adding a specific hopper size or configuring the output pressure to match your local concrete mix design. Keep you updated with real-time photos and videos during manufacturing, ensuring the equipment is built to your specifications.

Lifelong After-Sales Support

- Remote Guidance & On-Site Commissioning: Expert engineers provide online troubleshooting or travel to your site for installation, debugging, and operator training.

- Proactive Annual Maintenance: We schedule on-site visits to inspect critical wear parts like the hydraulic system, pumping cylinders, and S-valve, ensuring long-term reliability.

- Localized Spare Parts Network: With branches in the Philippines, Pakistan, Indonesia, Malaysia, and Uzbekistan, we guarantee fast delivery of essential spare parts like wear plates, seals, and grinding rings to keep your project on schedule.

Although AIMIX can provide best concrete mixing pump trailer service, you may be still worried about whether you can gain returns after investment. You can get some details about the ROI of pump mixer concrete.

How About The Return on Investment of Concrete Mixing Pumping Machine?

The return on investment (ROI) of a concrete mixer pump is a crucial factor for contractors and investors when evaluating its profitability. Investing in a cement mixer pump is generally worthwhile, as it enables faster project completion, reduces labor costs, and improves construction efficiency. Most customers recover their investment within approximately three months of purchase.

How to Calculate the ROI of a Concrete Mixer Pump?

The ROI depends on several key factors, including:

- Purchase Price: The initial purchase price of a concrete mixer pump typically ranges from $20,000 to $30,000, depending on the model, capacity, and features.

- Raw Material Costs: The cost of cement, aggregates, and other materials used per batch.

- Labor Costs: The reduction in workforce required compared to traditional mixing and manual transportation.

- Output Capacity: The hourly concrete output, generally between 30 to 40 m³/h for small and medium-sized models.

- Daily Work Efficiency: The number of hours the machine operates per day and the number of working days per month.

By assessing these variables, you can estimate how quickly you can recover investment and generate profits. If you need assistance in calculating your ROI based on specific project needs, our sales team is available to provide detailed guidance!

How Does A Cement Mixer With Pump Work?

There are six steps through the whole construction process.

Drag the cement mixer with pump to the construction site with the help of a tractor

Set the cement pump mixer at a proper place and then connect delivery pipe with the it.

Feed concrete into the mixer.

Concrete is mixing in the drum.

Concrete gets into the pumping system and then goes out through pipelines.

Clean the pipe in order to avoid the waste of spare concrete or the blockage in pipelines.

What Are the Differences Between Concrete Mixer Pump and Trailer Concrete Pump?

Trailer pump and concrete drum mixer pump are the main hot-sale concrete pumping equipment in AIMIX. A lot of customers are puzzled about what differences between them and which one should be chosen for their construction projects.

Whether Equipped with Mixer

The main difference between trailer mounted pump and mixer pump is whether have concrete mixer or not. The small concrete mixer and pump is the combination of concrete mixer and concrete pump. It has a double function: mixing and pumping. While the trailer type is just one piece of pumping equipment. Both of them are mobile concrete pumps.

Capacity Difference

Another difference is capacity. Trailer concrete pump has a wider range of capacities about 40 m3/h to 80 m3/h, which is suitable for medium and large construction projects. While the cement mix pump has a smaller capacity of about 30 and 40 m3/h, which is appropriate for small and medium construction items, such as roads, houses, low-rises buildings, and bridges…..

Price Differences

Larger capacity, higher price. Under the same capacity, the mobile concrete mixer with pump price is higher than trailer concrete pump price. Because, it has an additional concrete mixer equipped.

Thus, if you only machine with only pumping function, trailer pump is enough for your project. If you want to add its mixing function, the concrete mixer pump will be your best choice. If you want to get best mobile concrete mixer pump price, welcome to contact us through the following form.