Struggling with limited space, high labor costs, and logistical headaches on small concrete projects? Traditional mini concrete mixer falls short. AIMIX redefines compact construction with our innovative mini self loading concrete mixer.

It combines mixing, loading, and transporting into one efficient unit operated by a single person, revolutionizing how we approach construction tasks. Whether you’re working on a residential project, a rural road, or a confined urban site, this equipment offers a smarter, faster, and more cost-effective concrete mixing solution.

Beyond Tradition: Why Our “Mini Self-Loader” is Not What You Think

Forget the small, passive drum you know. While a standard concrete mixer mini just mixes, our mini self loading concrete mixer are similar to complete, mobile concrete batching plant on wheels. It actively loads raw materials, precisely mixes, and delivers concrete right where you need it. This fundamental shift from a simple mixer to an intelligent, self-sufficient system solves the core inefficiencies of traditional small-scale work.

Core Components and Workflow

- Loading System: A hydraulic bucket collects raw materials directly from the ground or a stockpile.

- Mixing Drum: The drum rotates to blend materials into high-quality concrete, ensuring uniform consistency.

- Discharge Mechanism: A controlled chute directs the mixed concrete to the desired location with precision.

- Weighing System: new weighing technology integrated, ensuring accurate proportions for concrete mixing, with weighing accuracy over 98%

- Mobility: Compact size and robust wheels allow easy movement across rough or confined terrains.

Key Difference: Traditional Mini Mixer Machine vs. AIMIX Self Loading Mixer

|

|

|

|---|---|---|

| Features an integrated hydraulic loading shovel. The operator loads materials directly from the pile into the drum from the driver’s seat. | Loading Mechanism | Require a separate loader (e.g., skid steer) or manual labor to load sand, gravel, and cement into the drum. |

| Streamlined process: drive to material pile → self-load → mix while driving → discharge on-site. | Operational Workflow | Multiple steps: transport materials to mixer → load → mix → discharge → transport wet concrete to site. |

| Designed for true one-person operation, drastically cutting labor costs. | Labor & Cost Efficiency | Often needs 3-5 people for efficient operation. |

| A robust 4-wheel drive vehicle that accesses tight spaces like backyards, narrow alleys, or finished interiors. | Mobility & Accessibility | Often stationary or trailer-mounted, limiting on-site placement. |

Your Solution for Mini Concrete Mixing: Explore Our AS-1.8 & AS-2.6 Models!

AS-1.8 – Enhanced Capacity for Versatile Projects

- Capacity: 1.8 m³/batch, about 7.2 m³/h

- Engine Power(W): 78

- Mixer drum capacity (L): 2680

- Water tank (L): 400

- Weighing method: Automatic hydraulic weighing system

- Overall size (LxWxH): 7300×2650×3750

- Applications: essential for small to medium-sized projects, like foundation work, self-built house construction, road repiring, etc.

AS-2.6 – Heavy-Duty Performance for Rigorous Applications

- Capacity: 2.6 m³/batch, about 10.4 m³/h

- Engine Power(W): 78

- Mixer drum capacity (L): 3580

- Water tank (L): 500

- Weighing method: Automatic hydraulic weighing system

- Overall size (LxWxH): 7860×2750×4100

- Applications: suitable for low-rise building construction, precast concrete pouring project, rural concrete roads construction projects.

Which Types of Projects Demand the Mini Concrete Mixer – Big Performance in Tight Spots

Our mini mixture machine design conquers space constraints. Its compact footprint and agile maneuverability make it ideal for:

- Residential Projects: Backyard patios, swimming pools, driveway extensions, and interior construction where access is narrow.

- Municipal and Urban Development Projects: Sidewalk repairs, alleyway paving, curb installations, or street furniture construction.

- Road and Pathway Repairs: Road and pathway repair projects. quickly mix and deliver concrete for pothole filling, crack repairs, or sidewalk reinstatement

- Rural & Agricultural Construction: Building foundations, fences, or irrigation channels in remote areas with limited equipment support.

The Popular Choice in Construction

As a leader in innovative construction machinery, our mini cement mixer for sale has gained global popularity due to their unique advantages. With the booming construction industry, the demand for efficient and reliable mixers is on the rise. AIMIX has exports a variety of mini self loading concrete mixers worldwide, empowering customers to maximize their operational efficiency. Explore how our customers effectively utilize these mini concrete mixers in their projects and elevate your work quality!

Cement Mixer Mini Applied for Factory Construction

- Model: AS-1.8

- Capacity: 7.2 m3/h

- Application Place: Chile

Self Mini Mixture Machine Used for Road Project

- Model: AS-2.6

- Capacity: 10.4 m3/h

- Place: Morocco

Mini Mixer Concrete Used for Substation Foundation

- Model: AS-1.8

- Capacity: 7.2 m3/h

- Application Place: Philippines

Self Loading Mini Beton Mixer for County Road Project

- Model: AS-2.6

- Capacity: 10.4 m3/h

- Application Place: Kazakhstan

Hear from the Global Users: Real Reviews of AIMIX Mini Concrete Mixer Machine!

In the fast-paced world of construction, the right tools can make all the difference. AIMIX mini concrete mixer for sale has gained popularity among builders and contractors worldwide, thanks to their efficiency, convenience, and robust performance. But don’t just take our word for it. Let’s dive into the real reviews of global users who have used mixers in their projects.

- We have been using AIMIX AS-2.6 mini concrete mixture machine on our medium-sized construction sites, and it has been a fantastic investment. The larger capacity and powerful engine make it perfect for our projects. The self-loading feature has significantly improved our productivity.” – Mark from Indonesia

- AIMIX self loader concrete mixer machine mini are a reliable choice for small-scale concrete work. The machines are well-built, and the controls are user-friendly. The support from the AIMIX team has been excellent, providing us with technical assistance whenever needed.” – Emily from Philippines

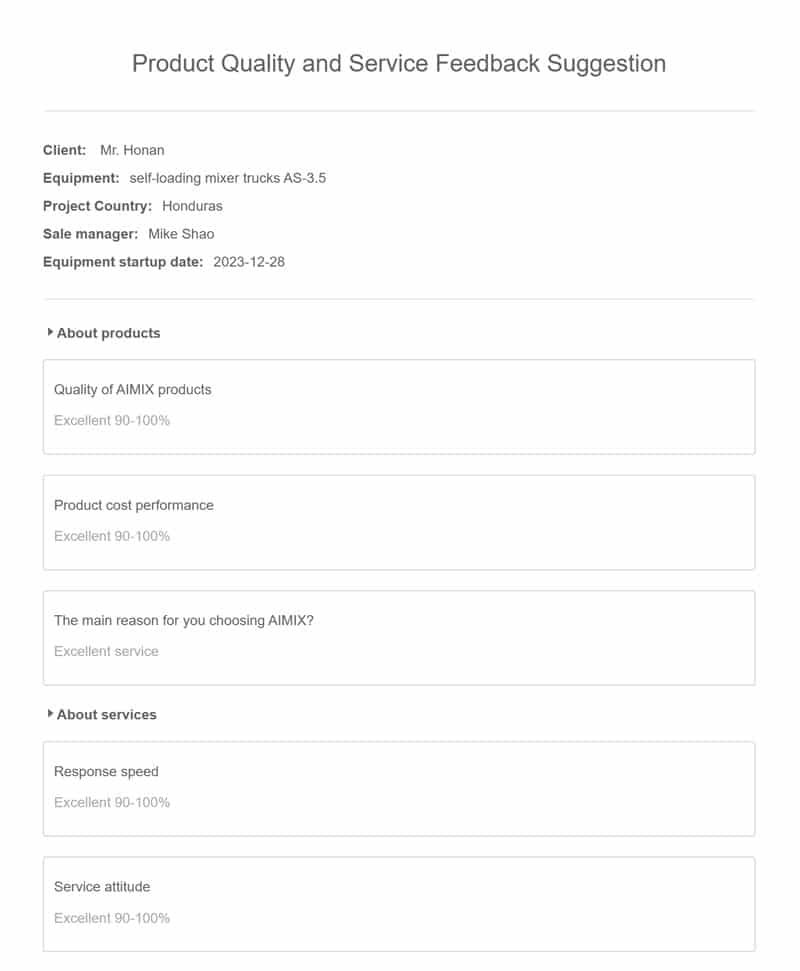

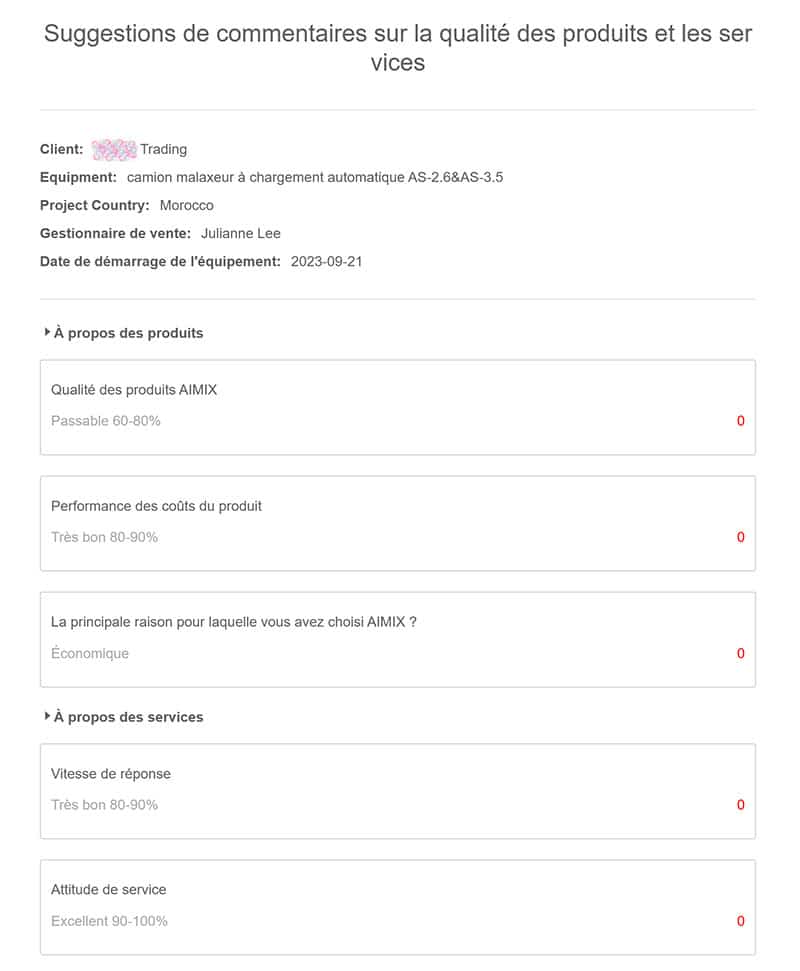

Here are also some satisfaction questionnaire for the concrete mixers:

Mini Concrete Mixer Price: What You Pay, What You Gain

Choosing a mini concrete mixer isn’t just about the equipment purchase price. It’s about the savings it unlocks on every job. AIMIX mini self loading mixers are built to cut labor costs, boost daily output, and reduce material waste, so you recover your investment faster.

Why AIMIX Delivers Better Value

- Built to last: High-strength steel and proven components for tough job sites.

- Reliable performance: Consistent mixing quality for small pours or full-day production.

- Real ROI: Fewer workers, faster cycles, and minimal leftovers lower your cost per m³.

- Flexible deals: Volume discounts and tailored configurations to match your workflow.

What You can Expect in Returns

- Transparent pricing: The AS-1.8-AS-2.6 mini concrete mixer machine price range is $15,000–$21,000. Final price depends on configuration (engine options, tire type, weighing system, cabin features) and destination.

- Payback period: Typically 6–12 months under standard utilization

- Labor savings: Up to 50%

- Productivity gain: 60% higher daily throughput

- Waste reduction: Leftovers cut to <25%

Tell us your target daily volume and delivery city or port. We’ll send a tailored quotation, payback estimate, and cost-per-m³ analysis within 24 hours. Multi-unit discounts available.

The Future of Mini Cement Mixer Machine in Construction

The construction industry is moving towards automation, efficiency, and sustainability. The mini concrete mixing machine self loading type is at the forefront of this shift. Here’s why its future is bright:

Growing Demand for Small-Scale Solutions

Increasing urbanization and the need for infill development drive demand for compact equipment.

The rise of small contractor markets creates new opportunities.

Technological Advancements

Integration of GPS, telematics, and IoT for real-time monitoring and optimization.

Development of electric and hybrid models for reduced environmental impact.

Economic and Environmental Benefits

Lower operational costs make these mini cement mixers an attractive investment.

Reduced material waste and emissions align with global sustainability goals.

AIMIX’s Role in Shaping the Future

We continuously invest in R&D to enhance our mixer machine mini lineup.

Our focus on customer feedback ensures our products meet evolving market needs.

Ready to build faster, smarter, and greener? Equip your team with an AIMIX mini self loading mixer and turn tomorrow’s advantages into today’s results. Let’s shape the future of construction—one efficient pour at a time.

Welcome to contact us right now and get every details about the mini concrete mixers. Contact us through the following inquiry form, email, or WhatsApp!