Choosing the right concrete batching plant manufacturers is a critical step for any construction business aiming for long-term success. Whether you’re building roads, residential complexes, or industrial infrastructure, a high-quality concrete batching plant ensures reliable concrete production and smooth project execution.

With numerous manufacturers across Asia, Europe, and other regions, it’s essential to identify manufacturers that not only deliver quality machinery and dependable service. Here, I break down what to look for in concrete batching plants manufacturers and why many global contractors rely on AIMIX Group as their preferred partner.

What to Look for in Concrete Batching Plant Manufacturers

For buyers, investors, and contractors, it’s essential to understand the key factors that differentiate reputable manufacturers from the rest. Here, I have highlighted the critical elements to consider when selecting concrete batching plant manufacturers.

Manufacturing Capabilities and Technological Expertise

- Production Strength: The first indicator of a reliable batching plant manufacturer is its production strength. Do they have in-house manufacturing workshops? Are they capable of producing large quantities while maintaining consistent quality standards?

- Advanced Manufacturing Equipment: Top-tier concrete batch plant manufacturers usually invest in CNC cutting machines, sandblasting workshops, and advanced welding lines to ensure equipment precision.

- Technological Innovations: Besides, technology matters. A manufacturer should offer batching plants with integrated PLC control systems, twin shaft mixers for better mixing quality, and energy-efficient designs.

- Performance Benefits: A high-performance concrete plant for sale can reduce material waste, minimize labor costs, and accelerate construction timelines. All of these can contribute to better ROI.

Product Range and Customization Options

As we all know, not all construction projects are the same. A good concrete batching plant manufacturer will provide you with different equipment and provide customized service.

- Diverse Product Range: The best batching plant supplier will offer a diverse product range, maybe including: stationary type, mobile type, dry mix type, wet mix type, compact type, foundation-less type, etc.

- Customization Capabilities: Equally important is the ability to customize. You may require customized configurations to meet the construction requirements, like high-capacity silos, extra aggregate bins, skip hoist or belt conveyor feeding, or even integration with precast systems.

Certifications and Safety Standards

When evaluating concrete batch plants manufacturers, consider the following key aspects to ensure quality and reliability:

- Key Certifications: Certifications such as ISO 9001 and CE indicate a commitment to quality management systems and adherence to European safety standards, respectively. These certifications serve as a benchmark for the concrete mixer plant manufacturers’ reliability and operational excellence.

- Quality Assurance Protocols: Comprehensive inspection processes for all components before delivery. Attention to detail reflects the concrete batch plant supplier’s reliability and commitment to quality.

After-Sales Service and Support

Even the best concrete batching plant may face operational problems. That’s why after-sales service is a critical component of the concrete mixing plant manufacturer’s offering.

- Installation and Training: A reliable concrete batching plant company will provide on-site installation and training support, ensuring that your team is well-equipped to operate the concrete plant efficiently from day one. The initial training is crucial for optimizing performance and minimizing downtime.

- Spare Parts Availability: In addition, quick access to spare parts and wear components is essential for maintaining smooth operations. The concrete batching mixing plant manufacturers that can promptly supply these parts helps prevent extended downtimes, ensuring your project stays on schedule.

- Technical Support: Furthermore, having a technical support team readily available is invaluable. Whether through remote assistance or dispatching experts on-site, timely support can address any issues that arise, ensuring swift resolution and continued productivity.

Selecting the right concrete batching plant manufacturer is crucial for achieving optimal efficiency in your construction projects. By evaluating these factors, you can primarily select a reliable manufacturer capable of delivering high-quality concrete production solutions, like AIMIX Group reliable ready mix concrete batching plant supplier. Next, let’s explore why to choose us to start your concrete batching plant business.

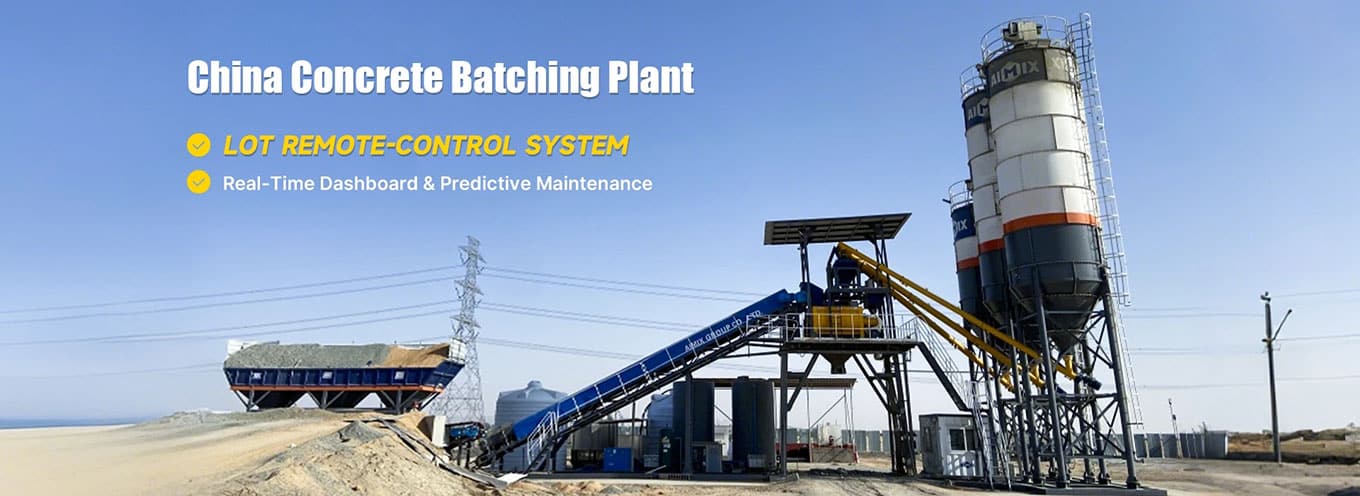

Why Choose AIMIX Group as Your Trusted Concrete Batching Plant Manufacturer?

While there are many concrete batching plant suppliers in the market, AIMIX Group stands out as one of the most experienced and globally trusted concrete plant manufacturers. Since its founding in 1982, AIMIX has been focused on delivering reliable, cost-efficient concrete production solutions to customers in over 150 countries. Here are six reasons why you can rely on us:

1. High-Quality Equipment

AIMIX concrete batching plants are built to deliver long-term performance, even under harsh conditions. The commitment to quality is reflected in every detail:

- Certified Quality: Comply with ISO and CE certifications, meeting global quality and safety standards.

- Premium Materials: High-grade steel and wear-resistant components extend service life by over 50%.

- Strict Quality Control: Undergoes rigorous inspection and full-function testing before delivery.

2. Advanced Technology That Drives Efficiency

AIMIX integrates cutting-edge technology into every aspect of its concrete batching plants, delivering smarter, more efficient production with lower operating risks and costs.

- Integrated Controlling: Dual-mode control with PLC touchscreen and physical buttons

- IoT Remote Monitoring: Real-time tracking of key metrics, faster fault detection, and response

- Precision Feeding: Production stability improving 20%; raw material waste reducing 10%

3. Customizability for Diverse Construction Needs

AIMIX stands out for its ability to deliver highly adaptable concrete batching solutions tailored to complex and varied jobsite demands. Custom features include:

- Application-based layout design: Configured to suit specific working conditions

- Flexible mixer selection: Vertical-shaft mixers or twin-shaft mixers

- Expandable aggregate bins: Aggregate storage bins can be scaled up to 300 m³

- Cement silo configurations: Vertical silos or horizontal silos

4. Expert Support and Service

AIMIX offers comprehensive service and technical support to ensure every batching plant runs smoothly from day one. Our support features include:

- On-Site Installation: Professional engineers provide guidance and support for quick and safe equipment setup.

- Operator Training: Customized training programs ensure your staff can run and maintain the plant efficiently.

- After-Sales Maintenance: Ongoing technical support and scheduled maintenance help prevent breakdowns and extend equipment life.

- Global Service Network: We have overseas branch offices and warehouses in key markets like Indonesia, the Philippines, Uzbekistan, and Malaysia for faster response times.

5. Competitive Price

Despite providing high-quality products, AIMIX batch mix plant manufacturer maintains competitive prices. They strive to provide the best value for money, making advanced concrete batching technology accessible to both small and large-scale projects. The concrete batching plant price list is as follows:

- AJ-25-AJ-50 Stationary Type: starting at $33000

- AJ-60-AJ-180 Stationary Type: starting at $78000

- AJY-25-AJY-90 Mobile Type: starting at $38000

6. Strong Reputation

AIMIX has earned a global reputation for delivering reliable batching plants and dependable service. Our client portfolio includes strategic partnerships with Fortune Global 500 companies and participation in critical national projects, like

- Military dock construction in Bangladesh

- National Fire Station Projects in Uzbekistan

- National Grid project in the Philippines

- Government-backed works in Malaysia

Types of Concrete Batching Plants in AIMIX Manufacturer

AIMIX, as one of the leading concrete mixing plant manufacturers in China, provides diverse concrete production solutions to meet global construction needs. Here are the key types of batching plants available:

AJ60-AJ240 Belt Conveyor Type Concrete Batch Plant

Features:

- High production capacity (60–240 m³/h)

- Fully automatic PLC control system for precise batching

- Belt conveyor feeds aggregates, ensuring smooth operation

Advantages:

- Higher Efficiency: Continuous feeding reduces downtime

- Suit for Large Projects: High-output requirements for large infrastructure projects

- Lower Maintenance: Durable belt system with long service life

AJ25-AJ50 Hopper Type Concrete Plant

Features:

- Skip hopper lifts aggregates to the mixer (25–50 m³/h)

- Compact structure, suitable for medium-sized projects

Advantages:

- Lower Initial Cost: More economical than belt type

- Space-Saving: Ideal for sites with limited horizontal space

- Faster Installation: Simpler structure reduces setup time

AJY25 – AJY90 Mobile Type

- Capacity: 25 m³/h to 90m³/h

- Design: The mobile concrete plant is integrated wheels/trailer for easy relocation

- Ideal For: Frequent site changes, like for rural roads construction, and small bridges construction

- Advantage: Quick setup, less than 3 days, minimal foundation work, and diesel/electric dual power

AJM Series Foundation-Free Batching Plant

- Capacity: 25–240 m³/h

- Mixer: twin shaft mixer

- Applied for: Temporary projects or locations with weak soil conditions, like middle asia and Africa desert areas

- Features: Modular design, no deep foundation required. Quick assembly and disassembly

- Advantages: Ready to use in 3–5 days; No heavy groundwork needed; Can be moved to different sites if needed

AJSY Series Compact Concrete Batching Plant

- Capacity: 25m³/h to 60m³/h

- Mixer: twin shaft mixer

- Application: Small concrete batch plant is applied for urban construction, small commercial projects

- Advantage: Noise-reduction technology, plug-and-play operation

Specifications

| Types | Hopper Type | Belt Type | ||||||

|---|---|---|---|---|---|---|---|---|

| Model | AJ-25 | AJ-35 | AJ-50 | AJ-75 | AJ-60 | AJ-90 | AJ-120 | AJ-180 |

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 75 | 60 | 90 | 120 | 180 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1500 | JS1000 | JS1500 | MAO3000/2000(SICOMA) | MAO4500/3000(SICOMA) |

| Mixer Power (kW) | 18.5 | 30 | 2×18.5 | 2×30 | 2×18.5 | 2×30 | 2×37 | 2×55 |

| Mixing Cycle Period (s) | 67 | 72 | 72 | 72 | 60 | 60 | 65 | 65 |

| Max.Aggregate Size (mm) | Φ60 | Φ60 | Φ60 | Φ80 | Φ60 | Φ80 | Φ80 | Φ80 |

| Standard Aggregate Bin Capacity (m³) | 3×3 | 3×5 | 3×8 | 3×12 | 4×7 | 4×15 | 4×15 | 4×20 |

| Category of Aggregate | 2/3 | 2/3/4 | 3/4 | 3/4 | 4/5 | 4/5 | 4/5/6 | 4/5/6 |

| Max. Discharging Height (m) | 3.8 | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 | 4.3 | 4.3 |

| Overall Weight (ton) | ≈15 | ≈18 | ≈23 | ≈30 | ≈40 | ≈68 | ≈93 | ≈101 |

| Installation Power (kW) | ≈65 | ≈75 | ≈100 | ≈140 | ≈110 | ≈160 | ≈220 | ≈290 |

| Power Supply | 380V/220V/415/440V, 50/60HZ, 3Phase | |||||||

| Model | AJY25 | AJY35 | AJY50 | AJY75 | AJY100 |

|---|---|---|---|---|---|

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 75 | 100 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1500 | JS2000 |

| Mixer Power (kW) | 18.5 | 30 | 2x18.5 | 2x30 | 2x37 |

| Mixing Cycle Period (s) | 72 | 72 | 72 | 72 | 72 |

| Max.Aggregate Size (mm) | Φ60 | Φ60 | Φ60 | Φ60 | Φ60 |

| Aggregate Bin Capacity (m³) | 4x4m³ | 4x4m³ | 4x5m³ | 4x6m³ | 4x8m³ |

| Powder Storage Silo (ton) | 1x50 | 1x100 | 1x100 | 2x100 | 3x100 |

| Max. Discharging Height (m) | 3.8 | 3.8 | 4.2 | 4.2 | 4.2 |

| Weighing Range & Accuracy of Aggregate (kg) | 2x900kg±2% | 2x900kg±2% | 2x1200kg±2% | 2x1800kg±2% | 2x2400kg±2% |

| Weighing Range & Accuracy of Cement (kg) | 350kg±1% | 500kg±1% | 600kg±1% | 1000kg±1% | 1200kg±1% |

| Weighing Range & Accuracy of Water (kg) | 200kg±1% | 200kg±1% | 350kg±1% | 450kg±1% | 550kg±1% |

| Weighing Range & Accuracy of Additive (kg) | 30kg±1% | 30kg±1% | 30kg±1% | 30kg±1% | 50kg±1% |

| Overall Weight (ton) | ≈15 | ≈20 | ≈25 | ≈31 | ≈37 |

| Installation Power (kW) | ≈65 | ≈75 | ≈90 | ≈125 | ≈180 |

Project Cases of Concrete Plants All Over The World

AJM75 Free Foundation Concrete Batching Plant

- Put into production time: April 2025

- Location: in Jeddah, Saudi Arabia

- Application: Used for a local substation project

- Site Engineer Feedback: “The free-foundation design of the AJM75 batching plant in Saudi Arabia was ideal for desert construction , adapting to unstable sandy ground without complex civil works, saving time and simplifying site relocation.”

AJ90Belt Type – Stationary Concrete Batching Plant

- Operational Time: April 21, 2025

- Location: in Papua, Indonesia

- Items: demand for on-site concrete for the power plant project

- Project site operator Feedback: “The integrated control system with dual operation modes is very convenient. The physical buttons are intuitive, and in complex situations, switching to the touchscreen. Uninterrupted production is efficiency.”

AJY60 Mobile Concrete Batching Plant

- Location: in Addis Ababa, Ethiopia

- Operational time: March 2025

- Application: commercial concrete production for real estate projects

- Configurations: 1m³ sicoma concrete mixer, 2x100T cement silos.

- General Contracting Feedback: “AIMIX’s customized mixing equipment is highly adaptable; one set can be used in multiple construction scenarios, significantly improving overall equipment utilization.”

AJ180 – Large Capacity Stationary Concrete Plant

- Put into production time: April 2024

- Location: in Kazakhstan

- Application: Used for commercial concrete production

- Maintenance Engineer Feedback: “Through the IOT system, the status of key components can be checked on the mobile phone at any time. The most recent one was a motor temperature warning. Timely processing avoided a major failure and really saved a lot of maintenance costs.”

Future Trends in Concrete Batching Plant Manufacturing

The concrete batching plant industry is undergoing rapid transformation, driven by automation, sustainability mandates, and AI-driven efficiency. Key trends shaping the future include:

AIMIX Keeping up with Technological Trends

AIMIX concrete batching plant manufacturer is already leading the way with integrated PLC+IoT systems, predictive maintenance features, and energy-saving configurations. Our smart concrete batching plants for sale support mobile control, remote diagnostics, and eco-efficient operations. AIMIX is keeping pace with global trends, delivering intelligent, sustainable, and high-performance solutions for clients worldwide. Contact us now to learn more and choose the right smart batching plant for your project.