One Machine, Multi-Functions – Mixing & Pumping & Placing

Transition Efficiency ↑60%360° Efficient Concrete Mixing

Export countries 150+Global 100+ Service Outlets

Boom concrete pump for sale is the ultimate pumping solution for fast, efficient, and high-rise concrete placement on today’s demanding construction sites. It consists of a concrete pump mounted on chassis with a long, articulated arm (or boom) that can extend and maneuver to reach different areas. Nowadays, it is widely applicable in all kinds of construction projects, especially for large construction items, like high-rise buildings, bridges, dams, etc.

At AIMIX, we offer two powerful options to serve different construction demands: one with an integrated concrete mixer for on-site mixing and pumping(15m, 18m, 20m, 26m, 33m), and the other without a mixer for high-volume pumping with ready-mix supply (33m, 38m, 40m, 47m, 50m, 58m, 63m). Let’s start with our versatile boom truck concrete with mixer.

With Mixer: Boom Concrete Pumps with Diverse Chassis Designs

AIMIX offers a diverse range of concrete pump trucks for sale with different chassis options, each tailored for specific operational requirements. The three primary types of chassis available are: crawler chassis, wheeled chassis, and truck chassis.

8-25m Crawler Type Boom Pump and Pan Mixer

- Boom length: 8m 15m 18m 20m 25m

- Max. Pumping Capacity: 50 m³/h

- Hot-sale Model: ABY-15 and ABY-18

- Applications: operate freely in mountainous areas, wetlands, and even rugged construction sites, greatly broadening the scope and efficiency of concrete pumping operations.

- Features It Attracts You: 35° climbing ability; 360° in-place steering; 60% better mobility in mud, desert, and mountains, ready for extreme jobsites.

20-33m Wheeled Type Boom Pumps with Pan Mixer

- Boom length: 20m 26m 30m 33m

- Max. Pumping Capacity: 89 m³/h

- Hot-sale Models: ABY-20 and ABY-26

- Applications: Easy to navigate through tight spaces and congested areas;

- Features It Attracts You: Engineering chassis structure design; 60% faster transitions; Without import restrictions on construction chassis concrete pumper truck.

30-38m Truck Mounted Concrete Boom Pump and Pan Mixer

- Boom length: 30m, 33m, 38m

- Hot-sale Models: ABY-30 and ABY-33

- Max. Pumping Capacity: 120 m³/h

- Applications: Suitable for projects, like high-rise buildings, bridges, foundations, slabs and large-scale industrial projects, etc.

- Features It Attracts You: Automobile chassis structure is adopted, and the transfer efficiency is increased by 60%, realizing “starting work upon arrival and transferring upon completion”

Integrated Pan Mixer, Unlimited Potential for Your Construction Projects

Without Mixer & High-volume Pumping: Different Models of Truck Mounted Boom Pumps

When it comes to efficient concrete placement, truck mounted concrete pump with boom stands out as the most popular concrete solutions in construction projects worldwide. AIMIX equipment has combined cutting-edge technology with robust engineering to ensure smooth concrete pumping operations. They are ideal for high-rise buildings, bridges, tunnels, and large-scale commercial projects where precision and power are essential. There are several boom length models for choice: 30m, 33m, 38m, 40m, 47m, 50m, 58m, and 63m. Check the boom pressure concrete pump models below.

What About Concrete Pump Truck Price?

Everyone concerns about the price of concrete pump truck. As we all know, the price of concrete boom truck for sale is not as cheap as other types of concrete pump machine. While, we can promise that Aimix can provide reasonable and competitive concrete boom pump truck price for global customers. As one of professional concrete pump truck manufacturers in China, we have produced concrete pumps for decades with mature technology. Therefore, the quality of equipment is ensured. AIMIX concrete boom pump price ranges are as follows:

- Wheeled chassis type: at least $60,000

- Crawler chassis type: at least $80,000

- Truck chassis type: at least $100,000

If you need the quotation, welcome to contact us right now. And before making an order, you also can do boom concrete pump price comparasion among different boom concrete pump truck suppliers for reference.

Benefits Of Using Boom Pump Concrete

AIMIX’s newly designed crawler-type and wheeled-type boom pumps for sale combine three key functions: on-site concrete mixing, pumping, and placing. Investing in one can significantly enhance the efficiency and productivity of your construction projects.

Dual Power, Smarter Savings

Equipped with a dual diesel and electric power system, the boom mixer pump delivers eco-friendly performance while significantly cutting operational costs.

Smarter Construction, Less Downtime

The integration of mixing, pumping and placing functions within one machine reduces boom concrete pump equipment transfers and setup delays. The result is a more streamlined workflow, ensuring working efficiency.

Effortless Concrete Placement

The flexible boom arm rotating 180° enables easy positioning and precise concrete distribution without the need for manual dragging or frequent repositioning. This reduces labor intensity, shortens pouring time, and ensures a smooth, continuous pumping process.

Enhanced Safety & Productivity

By eliminating the need to move heavy chutes or hoses, the boom system minimizes physical strain on workers and significantly reduces safety risks on site, especially when operating in confined or hazardous environments like tunnels.

Enhanced Reach and Versatility

With a flexible four, five or more section arm, the concrete pump truck for sale provides a large operational range. The unilateral support technology enables efficient construction even in narrow areas, making them ideal for a variety of project settings.

High Pumping Capacity

These boom pumps for sale are capable of delivering a high volume of concrete quickly, which significantly speeds up construction timelines. This efficiency is particularly beneficial for large projects where time is of the essence.

Energy Efficiency and Environmental Compliance

Designed with national standard emission regulations in mind, these pumps are more energy-efficient and environmentally friendly. This helps reduce the carbon footprint while maintaining high performance.

Simplified Maintenance and Reliable Operation

The hydraulic control system features automatic reversing, making maintenance straightforward and efficient. Additionally, the X-shaped outrigger design enhances operational stability and safety, ensuring reliable performance on any construction site.

Systems of Concrete Pump Truck

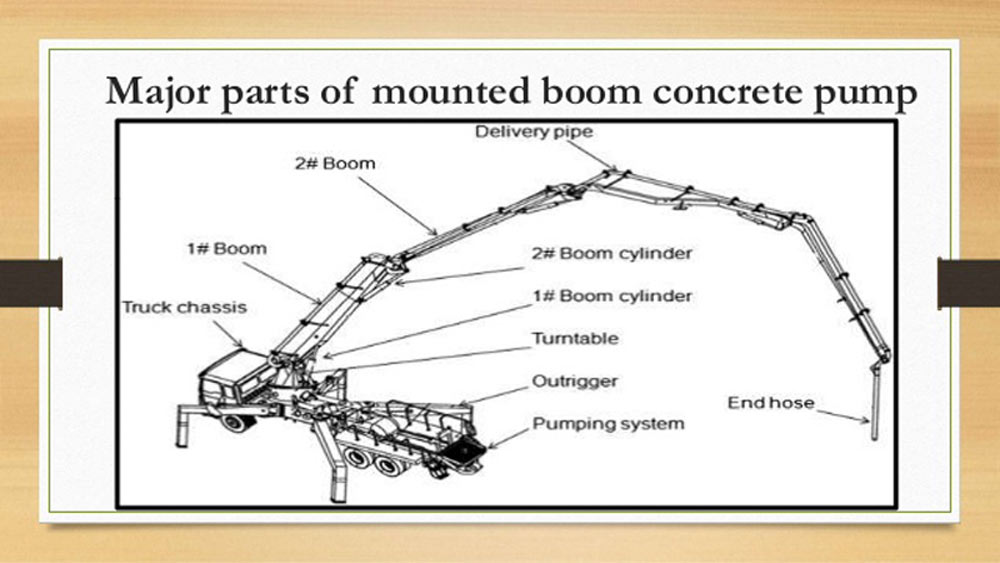

Cement boom pump is a high-efficiency concrete pumping equipment integrating driving, pumping and placing together. It consists of chassis part, boom system, pumping system, hydraulic system and electronic control system.

Chassis and Power System

Adopting famous Automobile’s heavy-duty chassis, which has strong bearing capacity, good power performance and low fuel consumption; it can achieve fuel saving, reduce energy consumption, and facilitate maintenance and other characteristics.

Hydraulic System

Full hydraulic control hydraulic system, oil pressure transferring signal, which makes the operation simple and reliable and improves the reversing speed of the swing cylinder. Moreover, it reduces the reversing impact, and at the same time the instantaneous action of the reversing of the large oil cylinder is accelerated and the concrete cylinder enrichment, which can make the continuity of the material strong and the material discharged evenly.

Pump System

- Large diameter conveying pipe, high power pump. Maximum displacement pump.

- Full stroke control technology: It can make the piston stroke of the pumping cylinder reach the position. In a reasonable time, the piston stroke of the concrete cylinder can reach the position, and has a higher suction efficiency.

- Flexible pumping control technology: check the pumping status, automatically adjust the movement of all mechanisms, realize the stable conveying of concrete, improve the efficiency of the pumping system, and extend the service life of hydraulic parts and structural parts.

- The key components are all from well-known international brands, featuring high efficiency and long life.

Boom System

- The boom system is made of Swedish SSAB steel plate, which has excellent fatigue strength and welding ability. The steel plate of the boom system is thicker and heavier. Pumping concrete is safer, more stable and precise.

- The boom frame is made of high-strength alloy steel with the latest structural design. Therefore, the weight of the swing arm is reduced, the mechanical performance is better, and the rigidity is higher.

- In the welding process, the Swedish ESAB solder wire is used.

- The rotating equipment in the boom system uses the products of German ROTHE ERDE or Italian companies. The material is 42CrMo, which has higher strength and service life.

Electrical Control System

The simple and reliable electric control system adopts Schneider brand to ensure stable performance. Equipped with two operation devices of panel and wireless remote control. Adopting well-known brand wireless remote control, it conforms to the principle of ergonomic design, beautiful appearance, light and flexible operation.

How Does Concrete Pump Truck with Boom Work?

The concrete pump truck with a boom works by using a hydraulic system to transfer concrete from the truck to the desired location. Here’s a step-by-step overview:

Concrete Discharge into Hopper

The process begins when the concrete truck unloads the concrete into the hopper located at the rear of the pump truck. A mesh grille in the hopper prevents large rocks or chunks from blocking the hoses, while a screw agitator keeps the concrete fluid by agitating it continuously.

Suction and Pumping

Once the concrete enters the hopper, it will be sucked into the valve system at very small intervals or strokes. When some concrete is sucked into the valve, the concrete is simultaneously pushed into the concrete pipe on the boom of the truck mounted concrete pump until it reaches the end of the concrete hose and is placed where you need it. As long as the hopper remains full and the concrete hose is not blocked, the process of pumping concrete will go smoothly.

Boom Distribution

The boom can rotate and extend, guiding the concrete hose to the exact area where the concrete needs to be placed. This allows precise and flexible placement even in hard-to-reach areas.

Continuous Operation

As long as the hopper remains filled and the hose remains clear, the system keeps pumping concrete continuously, ensuring efficient and smooth operations on the construction site.

What Should I Pay Attention to Before Running A Concrete Pump Truck?

Before running a boom pump truck, it is important to pay attention to operations. Timely checking and maintaining can prolong the truck’s service life. Here are some aspects you should pay attention to before running a pump truck.

Leakage

Due to machine loosening, vibration, and machine heating, leakage may occur at the sealing surface of the machine and the pipe joints. In the actual operation process, under the action of vibration and shock, oil (water) leakage (seepage) is exposed.

Loose Unit

In the processed and assembled parts, there are changes in geometry and matching dimensions. In the early stage of use, due to the impact of alternating loads such as impact and vibration, as well as the effect of thermal deformation, excessive wear is easy to cause. The originally tightened parts are loose. In order to ensure the normal operation of the machine, it is necessary to check the loose parts.

Fast Wear Rate

Due to the influence of factors such as the processing, assembly and adjustment of new parts of the concrete pump truck, the friction surface is rough, the contact area of the mating surface is small, and the surface pressure is uneven. During the operation of the pump truck, the uneven parts on the surface of the parts friction mesh with each other, and the ground metal debris is further involved in the friction, which accelerates the wear of the mating surfaces of the parts. At this time, if the concrete pump truck is overloaded, it may cause damage to the parts and cause early failure.

Well, these are only simple tips you should pay attention to before starting a concrete boom pump. Before operations, there are also some checking points. Operators should maintain it according to instructions.

FAQs

1. What boom lengths are available at AIMIX Group?

2. Does concrete boom pump truck for sale pump concrete vertically or horizontally?

Yes, vertically and horizontally pumping are all available.

3. How many operators are needed to run a truck mounted boom pump?

Typically, one trained operator is sufficient to control the boom and monitor the pumping process, though additional crew may assist with safety and hose handling.

4. Can a concrete truck with pump work in confined spaces?

Yes. the concrete truck pump for sale is equipped with flexible articulating arms and outrigger systems that allow safe setup and operation even in restricted areas.

5. Can the boom pump operate in extreme weather conditions?

Our boom concrete machine is designed for tough conditions, but extreme temperatures (below -10°C or above 40°C) may require additional precautions.

6. Do you provide after-sales service and spare parts?

7. Is concrete boom machine compliant with international standards?

8. What is the lifespan of the boom concrete pump?

9. What is the delivery time?

10. Can AIMIX customize the pump for specific project needs?

If you’re interested in learning more about our newly designed boom concrete pumps, whether crawler type or wheeled type, or have any questions about our concrete pumper trucks for sale, we’re here to help. Our professional sales and technical teams are ready to provide you with customized solutions based on your project needs, budget, and local working conditions. Feel free to get in touch with us at market11@aimixgroup.com or filling the following inquiry form. We guarantee a quick response and one-on-one service to support your construction business with the most cost-effective and efficient concrete pumping equipment.