Provide One-stop Concrete Production Solution

25 ~ 240 m³/h24/7 Customer Support

One-click StartIoT Remote-Control

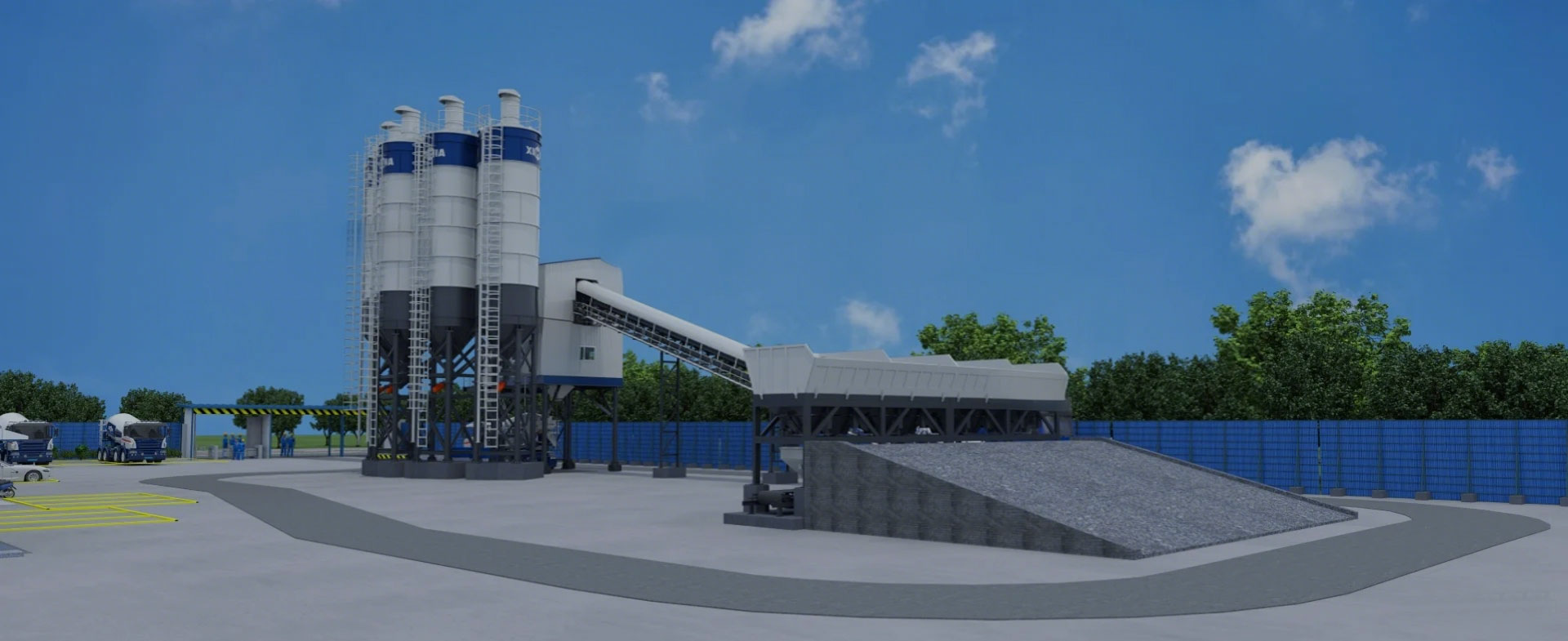

A wet mix concrete plant is a high-efficiency concrete production solution designed to deliver high-quality ready-mix concrete. Unlike dry mix concrete plant, it ensures thorough mixing of water, cement, and aggregates before discharge, resulting in higher quality, reduced segregation, and faster construction processes. It is ideal for large-scale projects requiring uniform mix quality, minimal on-site labor, and rapid batching, enhancing productivity while maintaining precision in every batch.

Which Type of Wet Mix Concrete Plant Is Best Suited for Your Projects?

As part of a comprehensive concrete production solution, wet mix plants are essential for infrastructure projects that require large volumes of concrete with strict quality control. For contractors, developers, and ready-mix suppliers, it is necessary for them to have a better understanding the type of wet concrete batching plant. As the choice of concrete plant can directly influence project timelines, costs, and final results.

Generally, there are two types of wet mix concrete plants for sale to choose from: stationary and mobile type. Each one has distinct advantages depending on project requirements.

Stationary Type Wet Concrete Plant

- Production Capacity: 25m³/h–240m³/h

- Hot-sale Model: AJ60, AJ90, AJ120

- Mixer Type: JS series twin shaft mixer

- Mobility: Fixed installation

- Project Duration: Long-term

- Best For: Large infrastructure, RMC production

Key Features & Benefits:

- High Production Capacity: Ideal for long-term projects (e.g., dams, highways, commercial complexes) with daily demands of 100m³ to 500m³ or more.

- Stable & Consistent Output: Fixed installation ensures precise batching and mixing, maintaining uniform concrete quality.

- Customizable Configurations: Can be equipped with advanced automation, multiple mixers, and silos for optimized workflow.

Mobile Type Wet Mix Plant

- Production Capacity: 25m³/h – 90m³/h

- Hot-sale Model: AJY35, AJSY40

- Mixer Type: JS series twin shaft mixer

- Mobility: Easily transportable

- Project Duration: Short-term or shifting sites

- Best For: road repairs, rural construction

Features & Benefits:

- Easy Transportation & Fast Installation: Mounted on trailers or skids, ensuring rapid deployment to remote or temporary job sites.

- Moderate Output Capacity: Typically produces 30m³ to 100m³ per hour, suitable for small to medium-sized projects.

- Minimal Site Preparation: Requires less foundation work, reducing setup time and costs.

Therefore, for large-scale, long-term projects requiring high-volume output and consistent quality, a stationary type is the ideal choice. However, if your project demands mobility, rapid deployment, and cost-effective solutions for temporary or shifting job sites, a mobile one offers greater flexibility and efficiency. Selecting the right type depends on your project’s scale, duration, and specific operational needs.

Wet Mix Concrete Plants in Action: Cases from Diverse Construction Projects

Now that we’ve explored the key differences between stationary and mobile wet mix concrete plants, let’s examine how these concrete production solutions perform in applications. The following cases show how AIMIX wet mix plants have addressed various construction challenges across different project types.

AJY60 in Singapore for Remote Road Work

- Plant Type: AJY-60 Mobile Wet Mix Concrete Batch Plant

- Capacity: 60m³/h

- Application: 200km expressway construction

- Requirements: Frequent 2-3 year once site transfers; Requiring a medium-sized and portable wet mix plant, and high quality equipment needed.

- Client Feedback: “The cooperation with AIMIX was very smooth again. The team was able to deliver quickly and helped me put the mobile concrete plant into production in less than 2 months.”

AJ35 in Malaysia for Commercial Concrete Sale Business

- Plant Type: AJ-35 Stationary Wet Mix Plant

- Capacity: 35m³/h

- Application: commercial concrete production and local sale business

- Requirements: First time to start this business, and requiring full support from purchasing to running the plant

- Client Feedback: “When finding concrete plant suppliers online, AIMIX is the fastest, most proactive, and most professional. They help me to solve the foundation construction problems when setting up. I will cooperate with AIMIX again in the future! “

AJ90 in Indonesia for PT Freeport Indonesia Power Plant Project

- Plant Type: AJ-90 Stationary Wet Mix Concrete Plant

- Capacity: 90 m³/h

- Application: power plant construction project in Papua

- Requirements: on-site mixing concrete mixture, accurate ingredients and high concrete quality

- Client Feedback: “AIMIX’s wet batch concrete plant delivered precise batching and high-quality concrete for our power plant foundations. Their team provided fast, professional support during setup and solved all technical challenges efficiently. Highly recommended!”

AJSY35 in Malaysia for Building Project

- Plant Type: AJSY-35 Mobile Wet Batch Plant

- Capacity: 35 m³/h

- Application: Residential community

- Requirements: small size due to limited space on-site and fast concrete production because of tight deadlines.

- Client Feedback: “The compact AJY-35 mobile wet mix plant was perfect for our tight worksite, enabling fast concrete production that helped complete foundation pouring 15 days ahead of schedule. Its on-site mixing capability saved us 30% in transport costs.”

Wet Mix Concrete Plant in the Context of Construction Industry Development

The global construction industry’s shift toward efficient, sustainable practices has positioned wet mix concrete plants as a pivotal solution. This evolution is driven by three key factors: escalating infrastructure demands, operational superiority over traditional methods, and continuous technological innovation.

High Growing Demand for Wet Batching Plant

The demand for wet concrete plant has surged due to several key factors:

- Urbanization and Infrastructure Growth: Governments worldwide are investing heavily in infrastructure projects such as highways, bridges, and smart cities. Wet mix concrete, known for its uniformity and durability, is preferred for large-scale projects where consistency is critical.

- Regulatory and Environmental Policies: Many countries have introduced stricter construction standards to enhance structural integrity and reduce environmental impact. Wet mix plants comply with these regulations by minimizing dust emissions and ensuring precise mix proportions.

Importance of Wet Mix Concrete Plants in Modern Construction

Wet mix concrete plants offer several advantages that make them indispensable in today’s construction industry:

- Superior Quality Control: Since the concrete is batched and mixed in a controlled environment, the risk of inconsistencies (such as improper water-cement ratios) is significantly reduced, leading to stronger and more durable structures.

- Reduced Wastage: Precise batching minimizes material waste, making the batching plant wet mix a cost-effective and sustainable choice compared to manual mixing methods.

Technological Advancements in Wet Mix Concrete Plants

Recent innovations have further enhanced the efficiency and functionality of wet mix concrete batching plant:

- Automation and IoT Integration: Advanced batching systems now use sensors and real-time monitoring to adjust mix proportions dynamically, ensuring optimal performance while reducing human error.

- Energy-Efficient Designs: New-generation ready mix plants incorporate energy-saving mechanisms such as variable frequency drives (VFDs) and solar-powered operations, aligning with global sustainability goals.

As infrastructure projects expand globally, wet mix concrete plants will play an increasingly vital role in shaping resilient and sustainable built environments.

Wet Mix Plant VS Dry Mix Plant: What’s the Difference?

In the construction industry, both wet mix concrete plants and dry mix concrete plants are widely used for producing concrete, but they differ significantly in their processes, applications, and advantages. Understanding these differences is crucial for contractors, engineers, and project managers when selecting the right batching method for their projects. Below, we compare the two types of plants in detail through a summary table for quick reference.

| Wet Mix Concrete Plant | VS | Dry Mix Concrete Plant |

|---|---|---|

|

VS |  |

| All ingredients are thoroughly mixed inside the plant’s mixer before being transported to the site. | Mixing Method | Only dry materials are batched and mixed inside the dry mix plant. Water is added either on-site or during transit in a mixer truck. |

| Continuous mixing, suitable for large volumes | Production Process | Batch mixing, ideal for smaller projects |

| More consistent and homogenous due to pre-mixing | Concrete Quality | Quality depends on proper mixing at the site, which can introduce variability. |

| Requires delivery of wet concrete, which has a limited time before setting | Transportation | Dry materials can be moved in bulk, reducing the need for special trucks. Water is added later to increase workability. |

| Ideal for large-scale projects (e.g., highways, dams, high-rise buildings). | Applications | Better for smaller projects or remote locations. Used in shotcreting and precast concrete production. |

| Generally takes longer to set up due to complex equipment | Setup Time | Quicker to set up and requires less space |

| Typically higher initial investment and operational costs | Cost | Lower initial costs; can be more economical for smaller projects |

Choosing the Right Wet Mix Concrete Plant for Your Needs

Selecting the most suitable wet mix concrete plant is a critical decision that directly impacts construction efficiency, project timelines, and overall cost-effectiveness. With various configurations and technical specifications available, it’s essential to evaluate key factors to ensure the chosen concrete batching plant aligns with your project’s demands. Below, we outline the primary considerations when selecting a wet mix concrete batching plant, followed by how AIMIX provides expert guidance to optimize your investment.

Key Factors to Consider When Selecting a Wet Mix Concrete Batching Plant

Production Capacity: Matching Output to Project Demands

Assess the expected concrete volume needed per hour or per day to avoid under-capacity (delays) or over-capacity (unnecessary costs). Then choose the concrete batching plant with different capacities and cycle time. The wet mix plants vary in batch sizes (e.g., 0.5 m³, 1m³, 2m³, 3m³ per cycle) and mixing speed, high-output projects need faster cycles.

Mobility & Footprint: Adapting to Project Site Conditions

Stationary wet mix concrete plants with large capacities, like AJ-90, AJ-120, AJ-180, suit large, long-term projects (e.g., dams, industrial complexes). While, the mobile wet mix plants are ideal for small and medium-sized road construction or remote sites, offering quick relocation. If there is a space constraints for on-site concrete plant operation, choose one with compact designs, like AJSY models.

Automation and Control Systems: Enhancing Efficiency

Consider the level of automation in the concrete plant’s operation. Advanced control systems can streamline processes, reduce human error, and improve overall efficiency. Modern AIMIX concrete plants have offered remote monitoring capabilities, ensuring real-time adjustments and data tracking to enhance productivity.

Budget Constraints & Long-Term ROI

Compare the total cost of ownership, which includes the initial wet mix plant price, operational costs, and maintenance expenses. A lower-priced concrete plant may not always be the most economical choice if it incurs higher operating costs over time. Higher automation may have a greater upfront cost but reduces labor and waste expenses over time. Besides, robust concrete plant designs with high-quality components can minimize downtime and repair costs.

How AIMIX Helps You Make the Right Choice

Every of you have different requirements for the construction projects. Therefore, AIMIX team would provide tailored consultations to ensure you select the optimal wet mix concrete batching plant by:

By partnering with AIMIX, you gain access to industry expertise, reliable equipment, and ongoing support, ensuring your wet mix concrete plant delivers maximum productivity and return on investment.

AIMIX’s Expertise in Wet Mix Concrete Production Solutions

With over 30 years of experience, AIMIX is a trusted global wet mix plant manufacturer. Our wet mix concrete plants are designed for durability and efficiency, supported by a comprehensive suite of services:

Custom Design and Configuration

We offer tailored designs to meet unique project requirements. Our engineers work closely with you to optimize wet mix plant machinery layouts and ensure seamless integration, maximizing output and efficiency.

On-Site Installation and Operator Training

AIMIX provides expert on-site installation services, ensuring proper setup and testing. We also conduct operator training sessions to equip your team with the skills needed for safe and effective machinery operation, reducing downtime.

Global After-Sales Support Network

Our commitment to client satisfaction includes over 100+ after-sales support network. With 24/7 assistance for maintenance and repairs, we ensure rapid response times to minimize operational disruptions.

Complete Concrete Production Solutions

We deliver end-to-end solutions, from consultation and design to installation and support. Our holistic approach helps you optimize processes, reduce costs, and achieve high-quality outputs in the competitive concrete industry.

In conclusion, AIMIX is committed to delivering exceptional wet mix concrete plant solutions tailored to your needs. If you’re ready to enhance your operations or become an AIMIX agent, we invite you to reach out to us. Contact us right now to discuss customized solutions and explore partnership opportunities with us!